MEMORANDUM

To: Professor Tsu-Jae King,

Microlab Faculty Director

From: Bill

Flounders, Technology Manager

Subject: 2007 Year-End Report

Date: 18 January 2008

Cc: Katalin Voros, Microlab Operations

Manager

I.

Introduction

This memorandum documents my major

activities for the calendar year 2007. For the past year, I have continued two

primary functions, planning for the CITRIS Nanofabrication Center (the planned

successor facility to the Berkeley Microlab) and, technology support for the

existing Microlab. Though design planning and construction review of the new

lab have been on going for several years, 2007 was the first year in which my

activities have begun to focus upon specific equipment and transitional plans

for the Microlab move in its new home in the CITRIS building. Calendar year

2007 is the year during which the Microlab transition and migration has shifted

from immanent to imminent!

I reiterate the following

information from last year’s report and henceforth will only use the assigned

names below for the CITRIS building and the new laboratory. At the CITRIS

Research Symposium on December 14, 2006 the lead benefactors to CITRIS were

publicly announced. The leadership private investors are: Dado and Maria

Banatao (parents of 3 UC Berkeley graduates) Sehat Sutardja (EE ’85, ’88) and

Weili Dai (CS ’84); and, Pantas Sutardja (EE ’83, ’85, ’88) and Ting Chuk (EE

’85). In recognition of their major investment and support of CITRIS: The

CITRIS Headquarters Building will be Sutardja-Dai Hall. Thanks to the

commitment and vision of the Sutardja and Dai families, cofounders of Marvell

Semiconductor, the successor to the Berkeley Microlab will be the Marvell

Nanofabrication Laboratory.

II.

Technology Support of

Existing Laboratory

Ebeam

Lithography

Calendar 2007 started with an exploratory visit by Crestec

Corporation of Japan. Crestec was established in 1995 and has become an

established supplier of electron beam writing systems. They have placed systems

in over 30 national laboratories and universities and at over 45 commercial

sites. However, they have yet to place a tool in North America. The President

of Crestec, Mr. Hideyuki Ohyi, and Product Manager, Mr. Peter Wilshurst were

visiting the United States to define a partner institution to showcase Crestec

capabilities to the North American and US market. They found a receptive

audience at UC Berkeley.

The Crestec flagship nanolithography system (the 9000

series) is not only a high performance tool capable of guaranteed writing of 10

nm line widths, it is also an extremely robust tool with a unique column

enclosure enabling more realistic vibration, EMI and temperature specifications

than many competitors, and a patented beam focusing strategy which enables very

high dose with smallest spot size. The Crestec tool also provides a wide array

of software features including absolute necessities such as multiple input file

type conversion and proximity effect exposure dose adjustment routines. All

review of the Crestec tool indicated it would be an excellent choice for a

general use ebeam lithography tool in a multi user shared facility.

As important as the quality of Crestec’s tool was the

willingness of Crestec to negotiate with the Berkeley Microlab. There was

lengthy discussion between the Microlab and Crestec; in the end, it was a model

of win-win negotiation. This was not simply an extended debate over acceptable

pricing. Rather, it was an exploration of multiple combinations of purchase,

lease and shared access that enabled both parties to define a solution

compatible with their needs. After months of hard work, a purchase agreement

was in place by the end of August. Berkeley sent an engineer to Japan for an

on-site review and demonstration in December 2007 and the tool is due for delivery

and install in February 2008.

Finally, the Crestec purchase was one of the finest examples of the shared laboratory culture that the Berkeley Microlab has been fostering for decades. Fifteen faculty representing three departments and two colleges contributed to the purchase of this tool. Contributions from a faculty at another UC campus were almost included. The confidential details of the Crestec purchase will not be disclosed in this broadly distributed public document; however, any Microlab Principal Investigator may contact me for more information.

Proposal Development

- I developed several equipment and research

proposals to generate support for the existing and future operation.

Primary among these was a proposal to the National Science Foundation

Major Research Instrumentation (MRI) program. A joint proposal was

developed and offered to the Stanley Hall Biomolecular Nanotechnology

Center (BNC) through the College of Engineering Associate Dean of

Research. This proposal requested funds for 2 key tools at the BNC and 2

key tools at the Marvell Lab. The thrust of the proposal was to insure

broadest possible access of researchers from across campus to both

facilities. NSF usually welcomes requests that leverage multiple

facilities and lead to research cross fertilization. Unfortunately, the

BNC elected to submit an independent proposal to the NSF MRI program so as

to insure receipt of the full grant award.

- I developed a separate proposal for the Marvell

Lab to the NSF MRI program. The primary equipment proposed was a set of

integrated wet process stations; unique to the proposal was distinction of

cleaning stations by periodic table group numbers rather than by research

group application. Though this strategy has merit –and will be implemented

for the operation of the Marvell Lab, the proposal was still simply a

request for nanolab sinks and as such does not meet the research

requirement of the NSF program. An alternate strategy has been developed

to provide wet process stations for the Marvell Lab.

- I developed a proposal to the Intel Higher

Education Semiconductor / Nanostructures Program. This proposal requested

funds for purchase of an on-site hydrogen generator to meet the needs of a

soon to be received Applied Materials epi-silicon germanium deposition

system. This proposal was funded and insures that a key piece of

laboratory infrastructure required for support of the epi-SiGe dep system

will be available.

Process

Review & Material Compatibility

I review at least weekly new material and process requests.

Some highlights from the past year were: evaporation of indium arsenide for

energy band pinning – alternate and much safer process offered was sputter

deposition of indium antimonide. PZT sol gel deposition and curing – approved

in non-MOS clean rapid thermal anneal tool. Chitin and chitosan processing.

These are structural proteins being investigated as a novel IR sensitive MEMS

layer.

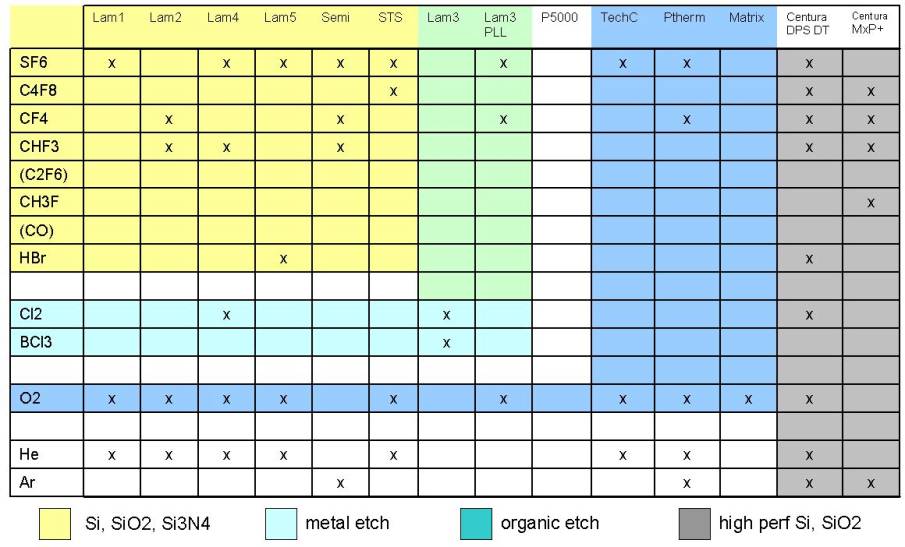

I have noticed a growing number of process questions

– especially by new BMLA members or the researchers of recently transferred

faculty members – related to “what tool is needed for what process.” This

reflects our growing lab membership and indicates the need for a more generic

tool/process overview in the Microlab manual. Together with the process

manager, I have begun to prepare tool table summaries that should enable lab

members to quickly compare the many redundant tools offered within a process

area and quickly compare them and understand the advantages of each. An example

of this type of tool table for etch processing is presented in Table 1. This is

an on going effort and will form the basis of the introductory process chapter

for the Marvell Lab on-line manual.

Staffing

The Technology Manager continues to provide direct

supervision of the BSAC Senior Development Engineer, Matt Wasilik. Matt has

successfully taken on most BSAC specific tasks previously provided by the

Technology Manager. A separate report describing his activities is included in the

Microlab Annual Report. Highlights of his report are detailed use histories and

failure analyses of the Centura and STS deep silicon etch tools; and, update on

the MEMS test structures integrated with the Berkeley Microlab baseline chip.

I served on the interview

committee for a second senior scientist for the Naofabrication Laboratory at

the Molecular Foundry at LBL. Three exceptional candidates presented seminars,

were interviewed, and received Berkeley Microlab overview/tours. This courtesy

was extended by the Molecular Foundry Nanofabrication Laboratory Director, Professor

Jeff Bokor. Ongoing coordination of the efforts at the Molecular Foundry and

the Marvell Lab are insured by this type of interaction.