MEMORANDUM

To: Katalin

Voros, Microlab Manager

From: Jimmy

Chang, Senior Development Engineer

cc: Sia

Parsa, Process Engineering Manager

Subject: 2007

Year-End Report

Date: 18 January 2008

In 2007, in addition to my regular work in process development and support, the highlights were process validation and support of Lam5 etcher upgrade, mentoring a summer intern in the project of correlating the sheet resistance and the thickness of aluminum film sputter-deposited in CPA, coordinating the production of 3 batches of show wafers for the Lam classes, and several new types of engineering test requests (ETR).

LAM5 Operation Software/Hardware Upgrade

Equipment staff upgraded Lam5

operation system to a Graphic User Interface. The upgrade included the addition

of a new computer for better user interface and enhanced recipe management. As

the result, the original on-board computer can concentrate on process/equipment

related controls. My work with this project included:

- Working with equipment staff to set up user

interface and security levels.

- Set up all standard recipes in the new interface

format.

- Validation of the etch processes to make sure

there was no process drift.

- Re-write on-line operation manual and

qualification quiz.

- Offered group training sessions for lab members

qualified for the old operation system.

Table I lists the summary results of the validation tests

after the upgrade. The main etch rate and non-uniformity are well within the

spec and the poly to oxide selective was much greater than 100. Lam5 has been

in service without any major problem related to the upgrade.

|

|

Blank

Wafer |

Patterned

Wafer |

||||

|

Main

Etch |

Main

Etch |

Over

Etch |

||||

|

Poly |

Oxide |

Poly |

Oxide |

Poly |

Oxide |

|

|

Etch Rate Å/min |

3911 |

375 |

4145 |

556 |

2848 |

20 |

|

Non-Unif. |

2.48% |

14.43% |

2.96% |

14.43% |

4.89% |

14.15% |

|

Selectivity |

10.4 |

7.5 |

143.5 |

|||

Table 1 - Lam5 Post Upgrade Process Validation Data

Correlation of Sheet Resistance and Film Thickness of Sputter-Deposited

Aluminum Film (A Summer Intern project)

In the summer, I mentored a female

high school student intern. The project I designed for her was to correlate the

sheet resistance and film thickness of aluminum film sputter-deposited in CPA.

It consisted of using most of the major tools in the Microlab. The student

learned how to use sink to clean wafers, Tystar furnace to grow thermal oxide,

CPA to sputter Aluminum film, four-point-probe to measure sheet resistance,

various photolithographic tools to pattern the film, Lam3 to etch out the

pattern, and ASIQ profiler to measure film thickness.

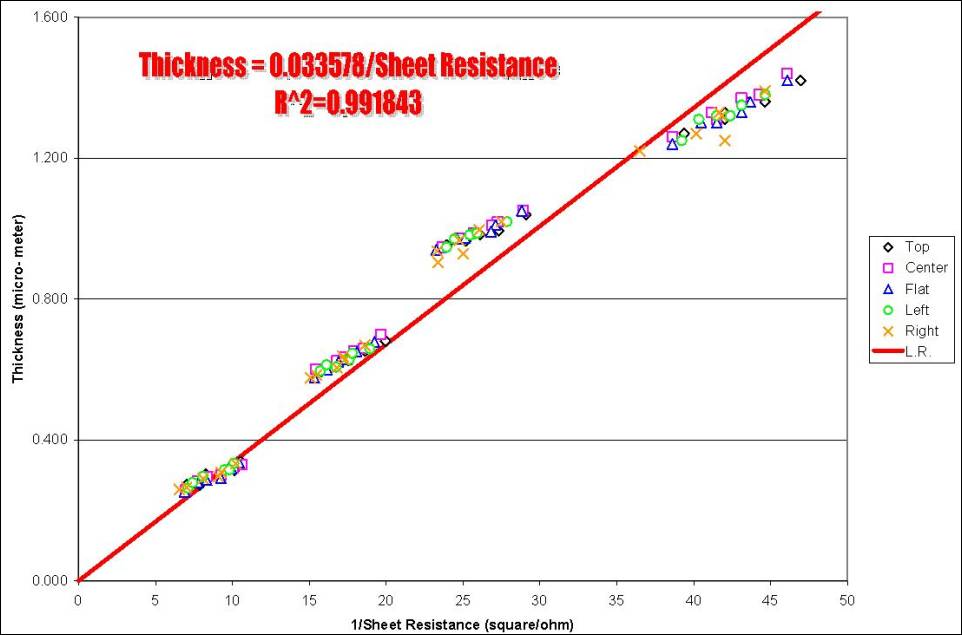

The program was successful. The student had an extensive

exposure to semiconductor processes and expressed strong interest in pursuing

an engineering degree in college. The correlation between sputtered Aluminum

film thickness and sheet resistance, shown in Figure 1, will be useful for the

Microlab. It can be used for a quick check of the CPA sputter deposition rate

and Lam3 etch rate without going through the tedious photolithographic

processes.

Figure 1 - Correlation of Sputtered Aluminum Film Thickness and Sheet Resistance

Show Wafers for Lam Non-Technical Staff Class

Last fall, Microlab hosts three sessions of classes for the non-technical staff of Lam Research Inc., a major equipment vendor of semiconductor industry. All the students in the class received a 6” silicon show wafer. I coordinated the process staff in production of the show wafers. It includes graphical design, mask making, thin film deposition, photolithographic patterning, etching, and wafer case selection. Thanks to all process staff, three batches, over 50 show wafers were made and delivered.

Engineering Test Requests (ETR)

In 2007, there were several new types of Engineering Test Requests in addition to the usual thin films deposition, e.g. oxide growth, poly, low stress nitride (LSN), doped/undoped low temperature oxide (LTO), and etc., in the past. They are list below.

- Lam2 etch of passivating oxide layer of III-V

compound devices for optical applications. Performed initial test runs

with satisfactory result. Then trained graduate students from UC Davis of

the process.

- AMST single-molecular layer deposition of FOTS

on packaged optical devices.

- Set up Lam5 and Ptherm for a BLMA member staff

to do special plasma characterizations and diagnosis.

- Oxford2 oxide deposition to protect manufactured

devices.

- Sophisticate wet etching on several kinds of

fused quartz samples to form multi-step surface profiles for an optical

company.

- Deposit poly-silicon films for UC Davis EE146A

laboratory class.

Support of Tystar Furnace Maintenance & Recipe Update

I have been working closely with

the equipment engineer in the area of heater calibrations, problem diagnoses,

communicate with the Tystar Company service Engineer, and final testing after

the repair.

In January, Tystar11 and Tystar12 were found to have a severe particles contamination problem. The contamination was suspected from films that contains volatile metal oxide. Changing of clean wafer boats and dummies did not solve the problem. To avoid changing the expensive quartz tube, a clean/purge process was developed to handle the problem. It consisted of a high temperature oxidation (800 ºC, 2 hours), followed by overnight pump and purge cycles with high flow of nitrogen. The cleaning process was successful and the contamination problem was solved.

Equipment Operation/Process Training

- Trained the new baseline engineer and MEMS

exchange engineer on the operations and processes of furnace, etchers, and

P5000.

- Provided semiconductor process orientation and

equipment operation training to high school summer interns.

- Trained new lab assistants (process student).

- Trained lab members on P5000 and Rudolph

Ellipsometer.

Miscellaneous

- Completed Engineering Test Requests from other

universities and research institutes.

- Changed CMP polishing head (4” &6”) when the

equipment engineer in charge was on leave or other assignment.

- Graded equipment quizzes, qualified lab members

on various tools.

- Lead monthly laboratory safety tours. Substitute

in the processing session of the orientation as needed.

- Revised the following manuals:

Chapters

5.5-6 - MOS

Clean Gate/Dry Oxidation and Annealing Atmospheric Furnace.

Chapter 5.7 - MOS Clean Annealing

Atmospheric Furnace.

Chapter 5.13 - Tystar13

Non-MOS Clean POCl3 Doping Furnace

Chapter 5.14 - Tystar14

Boron+ Doping Furnace

Chapter 5.16 - Tystar16

Non-MOS Poly-Silicon LPCVD Furnace

Chapter 5.18 - Tystar18

MOS Clean Aluminum Sintering Atmospheric Furnace

Chapter 7.5 - Lam5 Poly-Silicon TCP

Rainbow Etcher