MEMORANDUM

To: Katalin

Voros, Operations Manager

From: Kim Chan, Assistant Development

Engineer

Subject: 2007

Year-End Report

Date: 18

January 2008

cc: Sia

Parsa, Professor Andy Neureuther

This is a summary of the

activities and projects that I was involved during 2007

I.

SEMICONDUCTOR PROCESSING

I

have been working on special photoresist and lithography projects with the

Advanced Lithography Group.

- Thinned

CGR-2205 resist with PGMEA, spun coat wafers at various speed, baked,

measured thickness and R. I. Chose

to spin coat 1:3 CGR-2205 resist and ARC-600 anti-reflective coating on

wafers, baked, test exposed a wafer on ASML stepper, and developed it for

Marshal.

- Transferred

the 555A etched oxide sem picture files to Marshal. After Marshal did the EBL, I inspected

the cgr resist patterns under the microscope, took LEO SEM pictures on cgr

and zep resist patterns and printed some cgr resist patterned pictures for

Marshal. Measured oxide and zep

resist thicknesses on 3 wafer, bonded oxide/zep 3 wafer on 6 silicon

wafer with cool grease, baked, put under vacuum, etched oxide in

centura-mxp, measured oxide and zep resist thicknesses, debonded, cleaned

wafer and took sem pictures for Marshal.

Found zep resist didnt get clean in piranha bath, but needed

scrubbing in acetone and then piranha clean again. Took oxide pattern sem pictures on LEO

again after cleaning the zep resist and transferred sem picture files to

Marshal. Checked oxide etch information and etch time, zep resist

information and sent them to Marshal.

Printed zep overview sem pictures, took more zep sem pictures,

printed and sent them to Marshal for shotnoise experimental analysis.

- Grew 300A oxide

on wafers, measured oxide thickness on nanoduv and Rudolph

ellipsometer. After Marshal did

the EBL, I inspected the thin oxide, pmma and cgr resist EBL patterned

resist under the microscope and marked the wafers for sem work. Took sem pictures on pmma, cgr, krs and

zep EBL patterned resist wafers for Marshal. Bonded 3 cgr, pmma, krs and zep resist patterned oxide

wafers on 6 Si wafers with cool grease, baked, measured oxide thickness

and put under vacuum. Etched oxide

on cgr, pmma, krs and zep EBL patterned wafers in centura-mxp, measured

oxide thickness, debonded, cleaned wafers, took sem pictures and sent them

to Marshal for shotnoise experimental analysis.

- Looked for

missing SPIE 04 mask.

I

have been working on special projects for the Microlab process group.

- Cleaned and

lubricated GCA wafer stepper 2 and 6 stage rails, cleaned and lubricated

GCA pattern generator stage rails, and made masks for the Microlab while

Marilyn Kushner was on vacation.

- Grew oxide,

deposited PECVD oxide, ran the lithography process, etched oxide in

centura-mxp and etched the silicon (pocket) wafers in TMAH and centura-dps

for the RZE, Inc. in order to

produce pinhole free, 482 ΅m to 508 ΅m deep and 4 circular pocket on 6

wafers. First, started process

with standard I-line resist litho process on 6 oxide test and prime

wafers, exposed on ksaligner, etched oxide in centura-mxp, etched silicon

pocket in TMAH etchant and measured pocket depth. Found circular shape changed to octagonal

shape on silicon pocket, pocket was too small to fit 4 wafers and had

pinholes on pocket. Second, tried

SPR-220 resist litho process on 6 oxide wafers, exposed on ksaligner and

etched oxide in centura-mxp, partly etched silicon in centura-dps, finished

etching the silicon pocket in TMAH etchant and measured pocket depth. Found SPR-220 resist popped off the

wafer edge, sputtered onto the pocket area and prevented some oxide spots

being etched. Also found SPR-220

resist produced fine hairline cracks on oxide area during centura

etch. These fine hairline cracks

showed up on the oxide area after TMAH etch. Third, tried 2 ΅m I-line resist and S1818 resist litho

process on 5 ΅m oxide wafers, uvbake baked S1818 resist, etched oxide in centura-mxp,

partly etched silicon in centura-dps, TMAH etchant and measured

pocket depth. Found wafer edges

were thin, ragged and fragile after TMAH etch. Fourth, tried SPR-220 resist litho process on 6.35 ΅m oxide

6 wafers, exposed on ksaligner, hardbake some wafers for 15 hours and

more, uvbake one wafer 20 times with the flash recipes, etched oxide in

centura-mxp and etched silicon pocket in centura-dps. Found SPR-220 resist didnt hold up

during the deep silicon etch step.

Fifth, tried 100 ΅m

negative sheet resist litho process on 6.35 ΅m oxide 6 wafers, used a 4

silicon wafer as a mask to expose pocket pattern on ksaligner, etched

oxide in centura-mxp, partly etched silicon in centura-dps and finished

the silicon pocket etch in TMAH etchant.

Found silicon pocket was too small by using a 4 wafer as the

mask. Sixth, tried 100 ΅m negative

sheet resist litho process on 6.35 ΅m oxide 6 wafers, used a 4 silicon

wafer as a mask to expose pocket pattern on ksaligner, etched oxide in

centura-mxp and finished the silicon pocket etch in centura-dps. Found using 4 wafer as a mask, then

the silicon pocket turned out too small to fit a 4 wafer. Seventh, asked machine shop to make

101.5 mm, 101 mm, 100.5 mm disks and 102 mm ring metal mask set for

repeating the pocket wafer process with 100 ΅m negative sheet resist litho

process on 6.35 ΅m PECVD oxide and 2.35 ΅m thermal oxide 6 wafers, used a

4 silicon wafer as a mask to expose pocket pattern on ksaligner, etched

oxide in centura-mxp, finished the silicon pocket etch in centura-dps and

grew oxide to strength the pocket wafers as the final step of this

process. Finally, 101 mm and 100.5

mm disk masks produced the best fit for 4 wafers in the 6 pocket

wafers. Greg Mullins from RZE,

Inc. picked up three 100.5 mm masked pocket wafers.

- Cleaned and

tested parylene system until it worked well. Cleaned S. S. L. voltage multiplier stack in p-therm,

prepared parylene adhesion promoter and cleaned voltage multiplier stack

in it. Deposited 52 grams

parylene-c and measured the thickness for Bruce Dalen and Peter Berg from

Space Sciences Laboratory.

- Collected

PMMA process information, called Microchem Co. to check process

information, decided on process procedure, got price quote on PMMA resist

and PMMA Remover PG, calculated material and process cost. Confirmed ETR proposal, spun PMMA

resist at various spin speed to get the correct thickness, designed mask

layout, ran ebl exposure tests, exposed patterns on PMMA resist with

jeol107 sem at 18 KV and took sem pictures on the LEO sem for Dr. Yehiel

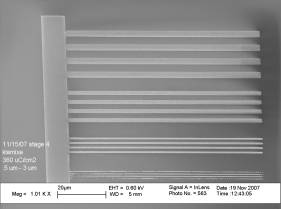

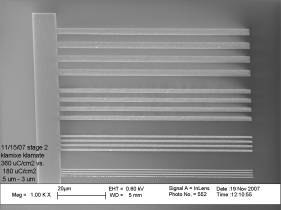

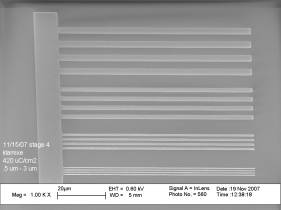

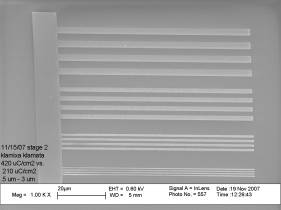

from KLA-Tencor. The following are

a few sem pictures to show the comparison of the standard exposures

and half dose/full dose exposures:

- Bonded Si to

Si wafers with cool grease for U. C. Davis a few times.

- Ran contact angle

measurement ETR on kruss.

- Assisted

Rosanna Cambie to coat AR3-600 anti-reflective coating, UV210 resist, ran

FEM, exposed Si and SOI wafers on ASML stepper, developed and inspected

them.

- Operated the

LEO SEM for Danny Xiong, took sem pictures from AMAT and sent him the sem

pictures.

- Collaborated

with Jimmy and Marilyn and made 65 Lam show wafers.

- Monitored

the phosphoric acid bath level on sink7 after the leak was fixed. Compared phosphoric acid bath

temperature reading to an external temperature thermometer. Monitored H2O drips to maintain acid

level. Checked nitride etch rate

before and after phosphoric acid evaporate.

- Showed Al

Briggs how to install the syringe properly on the Kruss system. Searched the websites for syringe

information, checked broken syringe information, related the information

to Al and tested the Kruss after it was fixed.

- Assisted a

lab member to swap wafer chuck parts on the Canon aligner, tried to focus

his sample on the aligner and went to machine shop for proper wafer chuck

screws.

- Gathered

wafer chuck dimension and vacuum grooves information on spinner1 and

svgcoat3, took pictures of wafer chucks and sent information to Dr. Y.

Gotkis from KLA-Tencor.

- Tried out

new software for matrix asher.

Processing

involved many silicon equipment and analytical instruments in the

Microlab. This year I learned how to

use the centura-dps system, flash process on uvbake system and negative sheet

resist process. Attended the wafersaw

training session and watched how to deposit FOTS film on amst system.

II.

EQUIPMENT & PROCESS MAINTENANCE

Equipment

Maintenance

- Rinsed

I-line resist line on svgcoat6 with acetone, rinsed resist bottle with

acetone, re-installed the bottle with acetone, primed the line with

acetone and kept the line soaking in acetone.

- Ran image

quality control and illumination uniformity tests on the ASML stepper.

- Tried to

solve the ASML stepper problems such as parameter out of range and lens

temperature errors.

- Ran wafers

to test the ASML stepper when there was a problem reported such as reticle

reading problem.

- Cleared the

Asyst smif pod loading and unloading problem.

- Worked with

Rite Track serviceman to see if we can resolve the resist coating defect

problem on svgcoat1 and svgcoat2.

- Checked

nanoduv reported problem.

- Checked and

cleared svgcoat6 and svgdev6 problems when needed.

- Checked and

corrected program recipes to solve problems on svgcoat1, svgcoat2,

svgcoat3 and svgdev.

- Replaced

I-line, G-line and SPR 220-7.0 photoresists on svgcoat1/2, SPR-220-7.0

photoresist on svgcoat3, I-line and UV210 photoresists on svgcoat6 and

primed the photoresist lines.

- Tried to

solve I-line resist pinhole problem after dispensing on svgcoat3.

- Assisted

David Lo to test svgdev6.

- Refilled

water in the chiller for the svgdev6 when needed.

- Disposed

resist waste and replaced new container on svgcoat6.

- Disposed

resist waste from 432c sink.

- Removed

stuck and broken wafers in Matrix chamber, restarted the matrix asher,

loaded recipe, reset heater and tested it

- Tried to

solve LEO sem focus problem and no signal input error.

- Assisted

staff on Disco saw and wafersaw.

- Assisted LEO

sem service representatives and checked LEO sem status when they were

working on it.

- Checked and

cleared gcaws6 problems such as removed stuck reticle, stage time out

error, RMS, Aldn, ACS, floppy drive, air pressure, light low and

auto-focus failure problems on gcaws6 when possible.

- Tested Sopra

ellipsometer after the software upgrade.

Checked Sopra ellipsometer log in and noise measurement problems

and measured thin oxide thickness on wafer.

- Checked

Quintel aligner problem and cleared it.

Checked jitter problem and related the problem to Phil until it was

fixed.

- Test vacuum

problems on parylene system and followed through until it was fixed.

- Checked

sink3, sink5, sink7 and svgcoat3 reported problems.

- Found

draining problem on sink7 bath and process codes changed. Changed process codes back to the

original codes. Monitored the

phosphoric acid bath level after the valve was fixed.

- Assisted

Changrui on gcaws6 while he was checking on how to back up the software in

the system. Arranged the hard

drive back up dates with Evan and Changrui. Labeled the wire connections to gcaws2 hard drive and gcaws6

Micro DFAS hard drive. Removed

gcaws2 hard drive and gave it to Changrui to clone. Tested gcaws2 and gcaws6 operations

after the hard drives were cloned.

- Tried to

assist when jeol107 sample holder was dropped into the jeol107 chamber.

- Cleaned lab,

restocked gowns and etc. for lab tour.

- Restocked

aluminum foil and cool grease in Y1.

- Tested

vacuum on spinner1.

Process Maintenance

I have been responsible to maintain general

photolithography processes for the Advanced

Photolithography Group. This

involved the following:

- Recycled

used 6 wafers.

- Piranha

cleaned beakers, graduated cylinders and small brown bottles for mixing

resists.

- Cleaned

individual wafer holders and labeled them to store 3 wafers for Marshal.

- Ran focus

tests on the asml stepper.

- Grew oxide,

measured oxide and resist thickness on nanoduv & Rudolph elllipsometer

on wafers.

- HMDS primed,

coated resists, exposed wafers, PEB, developed and inspected them.

- Inspected

wafers on the uvscope, took pictures on the uvscope and the LEO SEM when

needed.

- Checked and informed

DUV group on process data, equipment information and equipment status.

- Looked up

notes on flattened mask3 C. D. sizes, thin apex-e & thin cgr-2205

resist line width results for Marshal.

I

have been responsible to maintain part of the general photolithography

processes for the Microlab and the process group. This involved the following:

- Monitored

UV210 photoresist uniformity and thickness from svgcoat6.

- Monitored Eo

and illumination uniformity of ASML stepper using UV210 photoresist.

- Recycled

test, flat and ultra-flat silicon wafers to be used on the GCAWS6 and ASML

stepper.

- Cleaned 6

dummy wafers for svgcoat3, svgcoat6, svgdev6 and ASML stepper.

- Prepared

photoresist coated wafers for ASML stepper field servicemen and the

process group.

- Refilled developers

on svgdev6, EBR and HMDS on svgcoat6 when I see they are low. Restocked EBR in the lobby chemical

cabinet when it was reported out

- Cleaned and

dehydration baked wafers for processing.

- HMDS primed,

coated resists, exposed wafers, PEB, developed and inspected them.

- Monitored

the photoresist inventory on 6 wafer track, labeled DUV photoresists and

stored DUV resists and AR3-600 antiflective coating in refrigerators.

- Assisted lab

members in programming on the svgcoats and coating ARC-600.

- Sorted and marked

6 dummy wafers for svgcoat3, svgcoat6, svgdev6 and ASML stepper.

- Set up LEO

sem accounts for qualify users.

- Restocked

gloves, texwipes and printer paper in the LEO room when I see they are

low.

- Informed

Susan to order UV210-0.6 resist when it is low.

- Ran F/E

matrix, system focus, microscope rotation, baseline tests and made

corrections on gcaws6.

- Tested

programs on aptchrome and asked Tom to modify them.

- Refilled

developer in aptchrome.

- Tested

emulsion exposure problem on gcapg.

Tried the emulsion mask swapping procedure as suggested by Dick

Zegra from RZE, Inc., but was unsuccessful in solving this focus problem.

- Cleaned

gcaws6 FEM mask and svgcoat6 transfer stations.

- Checked SSH

transfer client operation and file saving commands on kruss system.

- Checked the

resist lift-off procedure and searched for usaf mask information as

requested.

- Assisted Yi

Du and Linjie Zhou from U. C. Davis on the cool grease bonding process.

- Assisted

Marilyn on working a show wafer for a retiring professor.

- Transferred a

little SPR-220 resist from svgcoat1 and svgcoat2 to a dropper bottle for a

lab member. Transferred some

SPR-220 resist from svgcoat1 and svgcoat2 to svgcoat3.

- Advised

Anita Pongracz to filter the AR3-600 anti-reflective coating when she had

granular problem.

- Assisted

Anita Pongracz to mix 100:1 HF in sink7.

- Showed Antal

how to set up EKC-270 resist stripper bath.

- Showed a lab

member how to expose wafers on ksaligner manually.

- Showed lab

members how to run FEM on gcaws6.

- Added EBR

program on svgcoat3.

- Checked spin

speed and spin time on srdsink8 and looked for SVC-14 resist stripper as

requested.

- Checked

Tystar13 and vacoven information for a lab member.

- Transferred

Design CAD file to a lab member.

- Cleaned

transfer boxes for sink5, brown bottles and labware.

III.

INSTRUCTION

& DOCUMENTATION

Instruction

- Instructed

and qualified researchers on equipment operation and fabrication

procedures when necessary.

- Showed staff

how to use sink3, gcaws6 and LEO S.E.M.

- Gave lab

tours for monthly orientation when needed.

- Assisted and

showed a few lab members how to use the

-

Wafer stepper 2 & 6

-

Kruss Contact Angle

Measurement System

-

LEO S.E.M.

-

Matrix asher

-

Memscope

-

Nanoduv

Microspectrophotometer

-

Svgcoat6 and svgdev6

-

Sink432A, sink432C and

sink3

-

Sopra ellipsometer

-

UVScope

-

Vacoven

- Qualified

lab members on the operation of the

-

Canon projection aligner

-

GCA wafer stepper 6

-

Headway spinner

-

Hummer sputter system

-

Jeol107 sem

-

Kruss Contact Angle

Measurement System

-

LEO sem

-

Matrix asher

-

Nanoduv

-

Nanospec

-

Primeoven

-

Quintel aligner

-

Sinkcmp spinner

-

Sinks

-

Sopra ellipsometer

-

SVG coat and develop

systems

-

Technics-c asher

-

UVScope

-

Vacoven

-

YES prime oven

Documentation

- Wrote daily

reports to Professor Andy Neureuther.

- Wrote weekly

reports to Sia Parsa for four months.

- Wrote cmpsink

report and mask clean chapter manual.

- Revised

process module 10 to 14, canon, gcaws6, heatpulse1 & 2, kruss,

svgcoat1, svgcoat2, svgcoat3, svgcoat6 and svgdev chapter manuals, gcaws2

& gcaws6 written quizzes, svgcoat3, svgcoat6 and svgdev6 posted signs.

- Graded asiq,

cpa, disco, gcaws2, gcaws6, jeol107 SEM, lam1-3, LEO SEM, Quintel aligner,

svgcoat6, svgdev6, svgdev, sinks, wafersaw and westbond lab quizzes.

- Input the

UV210-0.6 resist thickness and Eo data into the process monitor on the

Microlab web page.

- Recorded

gcaws6 F/E matrix test and baseline correction results on log book.

- Informed DUV

researcher on the progress of the processes by sending him e-mails.

IV.

SUMMARY

I had assisted Marshal

Miller on his shotnoise experiments, so he could analyze the data. I had prepared thin photoresists for him to

do the EBL in LBL. I grew oxide on

wafers, coated with various resists, ran preliminary exposure tests, etched

thin oxide patterns on wafers after Marshal did the EBL in LBL, stripped the

resists and took SEM pictures before and after stripping the resists and after

oxide etch for Marshal to analyze the data on his shotnoise experiments. I had assisted the Advanced Lithography

Group to run the experimental process well this year.

I had completed many ETR

runs, had assisted staff and lab members to make processes run smoothly in the

Microlab. I had assisted the Microlab

to maintain equipment when necessary to keep equipment in good running

conditions and minimize equipment down time. I had graded written quizzes and

qualified lab members on equipment so the lab members could use the Microlab

facility. I had revised chapter manuals, process modules and written quizzes to

keep them updated. I had made masks

when Marilyn was away on vacation so lab members could continue their

work. I had assisted the process group

to maintain the general processes in the lab to run smoothly this year.