MEMORANDUM

To: Katalin

Voros, Operations Manager

From: Sia Parsa, Process

Engineering Manager

Date: 18

January 2008

This memorandum

documents process engineering activities for the calendar year 2007. Last year,

I supervised the process engineering group comprised of 4 process engineers,

including; one MEMS-Exchange engineer, as well as the baseline research

associate, and average of three lab assistants (students) in the Microlab.

A great year, and many challenging

projects were successfully completed thorough effective team work between

process and equipment group, backed up by excellent engineering support in the

area of MEMS-Exchange program and baseline engineering.

Process staff tackled

quite a number of special application request/services. Interesting devices

were fabricated for MEMS-Exchange program, as well as custom pocket wafers for

lithography application, some of which were exchanged for free preventative

maintenance services and parts from one of our vendor companies. Process staff

also provided equipment training and generated new process recipes for our

upgraded poly etcher (lam5 Envision operating system upgrade). MEMS-Exchange

program was fairly active with a multi-design test chip run, and over 70

process steps performed on different runs at our site. Process staff provided

the same level of support to the Engineering Test Request (ETR) services with

interesting processes for Universities

and labs that made parts to go into space crafts.

The following summarizes

Process Engineering activities for this year.

II. EQUIPMENT UPGRADE

& NEW INSTALLATIONS

Esec 8003 Dicing Saw ( Wafersaw)

A

new Esec 8003 Dicing Saw (wafersaw) replaced our old broken down Disco machine

in August of 2007. This was a used saw,

in storage for a while, perhaps one of the reasons that it needed some issues

resolved on it. Daniel Queen compiled a list of improvements needed on this

tool, which resulted in the fabrication of a blade removal apparatus by the

Machine Shop. A replacement for the problematic height sensor that was

eventually damaged is on order. The

chuck vacuum sensing error was resolved by using dicing tape to hold the

samples on the chuck. A new lab manual

was posted online, and several equipment training sessions were offered by

Daniel Queen (08/07 & 09/07).

LAM5 Envision Upgrade

A

new Envision operating system and associated hardware resolved a series of

floppy and software corruption problems seen on our Lam5 machine, prior to the

September upgrade. All of our standard

recipes were reinstituted based on the new operating system. Poly-Si etch rate,

uniformity, and selectivity were then checked by process staff (Jimmy) on the

new set up, which trended well with the old process monitoring data. A few

training sessions were promptly offered by the staff to bring our lab members

on board in October. A new lab manual and qualification test were also

implemented at the same time, before releasing the tool, all of which were done

in record time without impacting the work in progress. The new Envision

retrofit has proven much more user friendly/reliable than the old set up, all

and all was a very successful joint project (equipment/process

engineering).

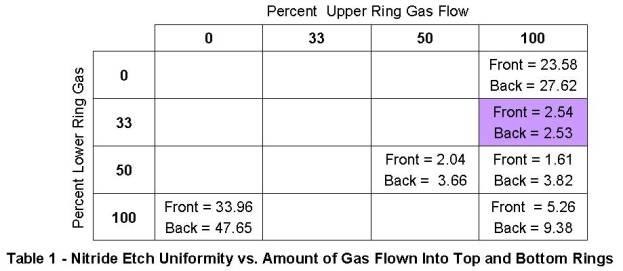

Technics-C Upgrade

The Technics-C plasma etcher was upgraded

(refurbished) with a flat lower electrode that eliminated the old pump port in

the center of the stage, and two gas feeds (one gas ring at the back of the

upper electrode, and another one at the front of the lower electrode). As a

result of this upgrade the tool can now take up to eight-inch substrates, also

produces an exceptionally great nitride etch uniformity. The experimental data

generated by one of our high school interns showed 2.5% etch uniformity for the

standard nitride etch process with a 100% flow at the top gas ring and 33% at

the bottom [two wafers were etched at positions F(front) and B (backside) of

the chamber], Table 1 below. These data

also points out a good across the chamber etch uniformity, much better than the

old single gas feed and center pump port set up.

III.

PROCESS DEVELOPMENt, sustaining & IMPROVEMENT

ACTIVITIES

ASML Mix&Match (Stanford and UC Berkeley

Steppers)

This year, I had the opportunity to

help the Stanford University with their new ASML stepper start up. This led to

further collaboration and the development of a Mix&Match process between

our two ASML 5500/90 (DUV) and 5500/60 (I-line) steppers. This required dropping our layout onto their

5500/60 templates for a 5" version of the ASML mask (ours 6"). We also selected one of our i-line resist

(Shipley S1818) for this study that was supported by the right kind of

developer at Stanford. I also forwarded modified version of our stepper jobs

that were easily loaded onto their stepper, all of which resulted in a

successful Mix&Match process. A nice collaboration work between the

Stanford and Berkeley labs made this development work possible. Special thanks

to Anita for quickly generating the required GDS layout files, Joanna

Lai/Alvaro Padilla (device group) for testing the Mix&Match process on

their products, Paul Jerabek for fabrication of our masks at Stanford, and Mary

Tang for coordinating the work and making their ASML stepper available to us in

a Six-inch form.

Other Process Support

- Tystar12

exhibited chronic particle problems at the start of the year. These were

embedded particles believed to have been caused by furnace leakage problem/s.

The equipment engineer in charge of our furnaces vacuumed the tube,

changed cantilever sheaths, injectors, and foreline filter canister to

eliminate leakage. He also switched the normally open type N2 MFC to a

normally closed type to minimize particle back streaming. The tube was

then pumped down and temperature calibration performed on it, which

stopped the particle generation.

Process staff ran a high temperature oxidation followed by an aggressive

N2 purge to clean out the remaining particles. This furnace is currently

in a good working order.

- Last

year, I helped Evan/field engineers identify ASML problems, also arranged

for field service, whenever maintenance/repair was needed. In June we

resolved a major alignment problem by having ASML field engineers change

boards, quad cells, and related connectors on ASML stepper to resolve our

wafer alignment issues. Shortly after this a small earthquake knocked the

laser off its position, therefore, more work had to be done to realign the

laser. ASML stepper is currently in a good working order.

- Many

special application jobs were set up by staff on the ASML, GCAWS2 and

GCAWS6 steppers. In the area of furnaces, process staff updated current

recipes, provided non-standard recipes for members, as per their requests,

and performed heater calibration on the furnaces, whenever needed.

- Due

to a long lead time associated with resist manufacturing/delivery, resist

usage was closely monitored by process staff to ensure no shortage would

occur. BARC and other support material were also monitored and ordered by

the process staff in a timely manner.

Lab Manual Write-Up, Process

Monitoring, and Qualification Test

This year, process staff updated

all the lab manual chapters assigned to them with revision dates older than 3

years (listed below). As always, BSAC engineer, Microlab equipment engineers

and technology manager, as well as selected number of Microlab members took

part in this overall effort to keep our 210 lab manuals up to date.

New and Rewritten

Manual

Chapter 4.33 - New chapter for Photomask cleaning

procedure (03/07)

Chapter 5.7 - New chapter - separating Tylan7 into its own individual lab manual (03/07).

Chapter 5.31 - Separated Heatpulse1 manuals - rewrite of

chapters (12/07).

Chapter 5.32 - Separated Heatpulse2 manuals - rewrite of

chapters (12/07).

Chapter 5.34 - New heatpulse4 chapter - Initial write up

(02/07)

Chapter 6.31 - New Chapter for the Ion Beam Deposition

System - initial write up (07/07).

Chapter 7.5 - New Chapter post Envision upgrade on

Lam5 poly etcher – rewrite (10/07).

Updated Manual Chapters

Chapter 1.3 - Major rewrite of MODs 1-14 in the

process modules chapter (09/07).

Chapter 1.7 - Updated Material & Process

compatibility chapter (02/07).

Chapter 1.8 - Defined process capability for the

Randex machine (07/07).

Chapter 1.9 - TMAH 90C added to the list of VLSI

etchants (06/07).

Chapter 2.1 - Updated the general cleaning chapter

(11/07).

Chapter 2.7 - Updated the sink7 VLSI chapter with Hot

Phosphoric process (08/07).

Chapter 2.10 - Modified sections 8.1, 8.2 and 9.1 of the

old sink chapter (06/07).

Chapter 2.12 - Updated sinkplate manual by removing

outdated information (06/07).

Chapter 2.14 - Updated sections 9.2.7 and 10.3 of

Tousimis CPD machine (08/07).

Chapter 3.1 - Updated gds file information in sections

2.3.5 and 2.3.6 (07/07).

Chapter 3.3 - Updated GCAPG manual (08/07).

Chapter 3.4 - Modified APT Emulsion operational

procedure for clarity (03/07).

Chapter 3.5 - Added the trouble shooting guidelines to

APT chrome chapter (07/07).

Chapter 3.6 - Modified guidelines for iron oxide mask

processing – section 9.0 (06/07).

Chapter 3.7 - Removed 2” plate, updated chrome to iron

oxide copying procedure (05/07).

Chapter 4.01 - Changed notes, and added section 8.6 to

SVGCOAT6 manual (12/07).

Chapter 4.02 - Updated the I-line resist information

(09/07).

Chapter 4.03 - Major update included; Mix&Match and

ASML operational procedure (12/07).

Chapter 4.04 -

Updated syntax errors and reference to the latest operating system (06/07).

Chapter 4.11 -

Added SPR-220 bake program (12/07).

Chapter 4.13 -

Major update of the GCAWS2 lab manual (06/07).

Chapter 4.14 -

Update of Canon lab manual (06/07).

Chapter 4.16 -

Update of Jeol lab manual (07/07).

Chapter 4.21 - Added troubleshooting guidelines for UV

bake machine (03/07).

Chapter 4.32 - Updated the General Resist Parameter

chapter (04/07).

Chapter 5.0 - Combined AP & LPCVD furnaces - Major

write up of overview chapter (07/07).

Chapter 5.14 - Minor changes in sections 5.2, 9.1.2,

9.2.10 and 9.2.11 for Tystar14 (05/07)

Chapter 5.15 - New deposition parameters for doped SiC in

Tystar15 (05/07).

Chapter 5.16 - Update of Tystar16 chapter (07/07).

Chapter 5.17 - Minor changes in sections 4.0, 8.0, 8.12,

9.2.4 and 9.3.4 for Tystar17 (04/07)

Chapter 5.18 - Updated references made to other chapters

in Tystar18 manual (05/07).

Chapter 6.02 - Extensive rewrite of Novellus m2i manual (06/07).

Chapter 6.03 - Added troubleshooting guidelines for

Randex System (07/07).

Chapter 6.07 - Updated available material for RF

deposition instructions (07/07).

Chapter 6.11 - Updated the operating section of the NRC

manual (03/07).

Chapter 6.12 - Updated the operating section of the V401

manual (03/07).

Chapter 6.15 - Added informational graphs to Ultek E-beam

evaporator (01/07).

Chapter 6.23 - Updated the AMST manual (10/07).

Chapter 6.28 - Rearranged operational procedure for P5000

machine (05/07).

Chapter 7.9 - Updated gases list on the Ptherm machine

(08/07).

Chapter 7.11 - Updated Technics-C lab manual – tool

retrofit (06/07).

Chapter 8.01 - Formatted the 4-point probe chapter

(04/07).

Chapter 8.03 - Equipment list update for IV probe chapter

(04/07).

Chapter 8.23 - Minor revision of the UV scope chapter

(03/07).

Chapter 8.33 - Formatted and edits the Nanospec chapter

(04/07).

Chapter 8.52 - Updated the Flexus manual – removed M:

drive reference (04/07).

Chapter 8.54 - Updated the contact angle manual – SSH procedure

added (10/07).

Process Monitoring,

Equipment Training, Member Qualification, and Test Grading

Our student helpers have

done a great job preparing wafer dummies, cleaning boats in furnaces, and

running test monitors on our baseline tools. Jimmy has directly managed their

activities in the lab, also provided support/training for the new student hire,

whenever needed.

This year a large number

of equipment qualification were performed, written test (graded), and oral

tests were given by staff for a number of tools. The BSAC and baseline

engineers also provided support in the DRIE etch, metrology, and CAD layout/

mask making areas. I assigned superusers on various tools and helped the

administration staff reinstate some of our members on their expired equipment

qualification.

IV.

process Staff

Supervision, TRAINING &

OTHER SERVICES

Staff Supervision: I supervised 4 process/MEMS-Exchange engineers, one baseline

assistant specialist, as well as one graduate, and three undergraduate assistants

working in the process group. Process staff yearly appraisals for staff

engineers were submitted on time, before the September 1st 2007 deadline.

Promotion and Awards: This year just about all the eligible individuals in the

process group received the SPOT award, among whom were two of our loyal

students graduates Raza and Peter.

Thanks for their 2 years of great service in the Microlab, and best of

luck to them.

New Student Hire: This year we hired three new lab assistants;

Eric Darmstaedter, Chris Zhao and Andrew Moe to replace Tessie Lee, Peter

Tabada, and Raza Uddin upon their graduation. The new students have done a

great job performing routine sustaining work and process monitoring on our

baseline tools.

High School interns: This year Microlab

was able to continue our 5 year old summer internship program with two new high

school students; Emmeline Lan and Carolyn Kooi. Thanks to Jimmy Chang (senior

process engineer) and Daniel Queen (PhD candidate) our interns were able to get

valuable experiences in the Microlab, each completed an interesting project in

the area of process optimization. The results of their experiments were

presented to the Microlab staff and guests at the conclusion of their summer

internship, as follows:

·

Aluminum thickness (T) monitoring through sheet resistance (Rs)

measurement was established as a viable method of monitoring CPA sputtering,

within 8.76% accuracy (T = 0.033578 / R), by Emmeline Lan.

·

Nitride etch non-uniformity was greatly improved (10X) in Technics-C

machine through the experimental matrix conducted by Carolyn Kooi, under the

mentorship of Daniel Queen, PhD candidate, and Jay Morford our equipment staff

engineer.

Microlab, EE143: Process staff provided services to the EE143

lab by ordering new furnace boats, and supplying them with their chemical

needs, and helping TAs with their poly/oxide runs.

Member advising, Help/Support of Other Universities, Institutions: Held weekly meetings with our technology manager discussing Microlab member special process requests. I also provided help/advise to UCB/LBL colleagues, other Universities and the industry.

- I

researched publications and advised one of our member companies how to get

rid of the impurity salt remaining, after MEMS parts were released in an

HF solution. Addition of HCL (~5%)

to the HF solution, as well as using HF resistance or pure SiO2 type

containers (Teflon or quartz Petri dish) could also help remedy the

problem. I helped the ASML application engineer qualify a new I-line

stepper at Stanford University. A portion of our baseline layout was used

on their 5" ASML template to check exposure and alignment on their

new tool. I also etched their printed zero layer on 25 six-inch wafers for

their alignment test.

- In

2007 , we assisted Professor K.

Teh with his grant proposal and equipment donation for his lab at San

Francisco State University.

V.

Semiconductor Processing

& special Services

ETR Services

For the past three years, we have been averaging around 25

engineering test requests per year. Last year staff successfully completed 24

ETRs with much faster response time, generating $32,820.79 in revenue for the

Microlab. In addition to the standard processing normally offered in the litho,

etch and the diffusion areas, we performed many other types of non-baseline

processes for other universities, which included; University of Michigan,

University of Texas, University of North Texas, Vanderbilt University, UCLA, UC

Davis, and SFSU.

MEMS-EXCHANGE

PROCESS service

This year we continued our services/support of the

MEMS-Exchange (MX) program. I supervised one MEMS-Exchange engineer assigned to

the task of processing MX runs in the Microlab. This year we generated

$63,019.22 in revenue, and 70 process steps were performed by our process

engineers on over 20 different runs at our site. Antal (Tony) Kovats joined the

staff in September, after Daniel left us for UCSF. Tony provided excellent

engineering service/support for the

MEMS-Exchange program. We held weekly meeting with the MEMS-Exchange engineers

discussing current/future runs, possible processing problems, as well as

evaluating and accepting new runs. One of the highlights of this year's

activity was the completion of Professor Lewei Lin’s second MX run at our site

(completed in 12/07). This run was a great improvement over the previous (1st)

run, called for a modified process flow/layout, and optimized DRIE. Also, a

special application HF vapor clamp designed by Matt Wasilik and paid for by the

MX program was used to make our job of HF releasing the MEMS structures easier

(separated die form). There were, however, still some issues remaining with

this run. A memorandum consisting of eleven counts of observations and

recommendations was submitted to the MEMS-Exchange engineer and Professor Lin’s

group in November. This report summarized design/fabrication issues that were

encountered, while processing the MX run 3506, some of which listed below,

Figures 1 and 2. The next and final

version of this run, also a multi-design test chip (3rd run) is

scheduled to start within a few weeks.

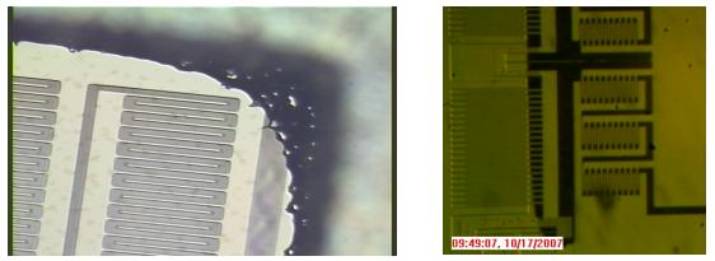

Layout

design and process Issues observed on the MX run 3506 included:

1. Backside mask layout modification will be needed for some of the MEMS

devices on the chip. These devices required

out of plane movement (Z-direction), therefore, openings must be completely

cleared along the entire perimeter, specifically at the corners, Figure 1.

Figure 1- Comb drives released by backside etch/HF vapor are

not cleared around edges.

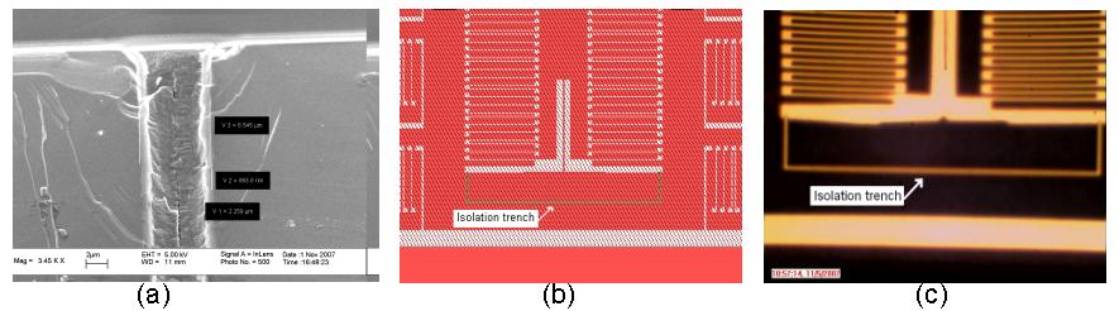

2.

Loss of poly in the isolation trench (process flow related). This

poly will be protected by a thin layer of

oxide in the next generation of the process flow.

Figure 2 - (a) Poly

Filled Isolation Trenches

(b) Layout Design of a Portion of a Large Mirror

(c) Optical

Microscope Image of the Same Structure as in (b), under the transparent light of a

microscope shows the poly loss in the isolation trench area.

Mask Making Services

A total of 930 new masks were processed on the pattern

generator in 2007 for our internal (UCB researchers and BMLA), as well as

external customers (other Universities) .

Special Requests

- Process staff developed a

special application process for six-inch pocket wafers that could be used

as carrier wafers in the lithography equipment. This required exploring

various methods of patterning the pocket area, as well as developing wet

and dry etch processes. Wafers were made to specification with a very

thick rolled on resist (100 µm), a relatively thick layer of oxide in the non-pocket

area, and a long DRIE process to etch out about 400 µm of silicon in the pocket area. The goal was to make

the top surface of a resist coated 4-inch wafer placed in the pocket area

flush with the adjacent non-pocket area in such a way that it will make

the task of auto focusing possible without exceeding the usable depth of

focus (UDOF). Some of these wafers were exchanged for free GCA stepper and

pattern generator service from RZ Associates.

- Process staff spent many hours

training/helping Pivotal Systems

staff engineer, as part of the agreement to exchange Microlab

membership and staff time for a TEL 300mm DRM etch system, which will be

installed in the new Marvell lab.

- Three sets of 25 show wafers

were promptly processed by the process staff in time for special

seminar/training sessions offered to non-technical staff at Lam Research.

Anyone attending one of these seminars at our site received a 6" show

wafer.

- Staff supplied the Microlab

office with the regular pocket wafers, as well as poly-Si control wafers

for general use in the Microlab.

VI.

CMOS Baseline activities

Third Baseline Run (0.35 µm Process)

This year, the baseline engineer Anita Pongracz started our second

0.35µm run (CMOS180), after reporting on the previous run CMOS170, which nicely

accomplished its main objective of

matching threshold voltages for P-channel and N-channel devices (Technical

Report No. UCB/EECS-2007-26). After the second metal layer deposition on

CMOS170, 1 μm gate length oscillators were tested for circuit

functionality. Average oscillation frequency of these oscillators were measured

at 62.2 MHZ. A full report on CMOS170 test chip is currently available at http://www.eecs.berkeley.edu/Pubs/TechRpts/2007/EECS-2007-26.html

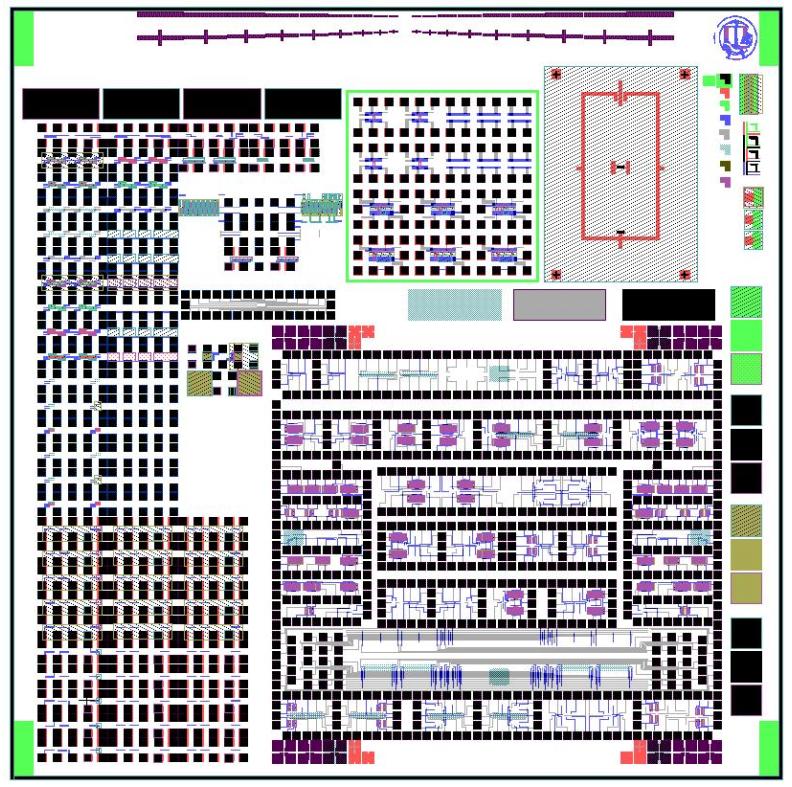

A new baseline test chip has already been taped out with baseline

test structures, three experimental ICs and MEMS structures designed by

staff/lab members. A new run, CMOS190

will soon begin fabricating these devices. Figure 3 shows the layout design of

the new test chip.

Figure 3 - Baseline CMOS190 Test Chip

VII.

REPORTS, PUBLICATION

& TRAINING

- Presented baseline capability

in the PI meeting (03/08/07).

- Memorandum – Summary report for

Professor Lin’s MX run submitted (11/15/07).

- Second 0.35 µm baseline report

submitted - Technical Report No. UCB/EECS-2007-26.

- Process staff attended BSAC IAB

seminars In September and February 2007 (1/2 day).

- Process staff attended the

Semicon West exhibition in July 2007.

- Process staff attended the

Solid State Technology and Devices Seminars on Fridays.

VIII. FUTURE GOALS/WORK

Future Upgrade, Process Development and Support

- Start a new baseline run on a

Mix&Match process (CMOS190).

- Take part in management

planning of the new Marvell lab.

- Continue support of the

MEMS-Exchange program & supervising of one MX engineer.

- Provide support for new tool

installations, and upgrades in the Microlab.

- Continue directing process

development/optimization activities on our current tools.

- Continue providing technical

support to BLMA and Microlab users.

- Continue updating equipment

manuals, and rewrites, as needed.

- Continue support of the summer internship and by

identifying projects for the interns.