MEMORANDUM

To: BSAC

Faculty Directors

William

Flounders, Microlab Technology Manager

From: Matthew

Wasilik, BSAC, Senior Development Engineer

Subject: 2008

Year-End Report

Date: 1

January 2009

cc: Katalin

Voros, Microlab Operations Manager

Professor Ming Wu, Microlab Faculty

Director

I have served as a development engineer for

the

I.

ENGINEERING, DESIGN, &

DEVELOPMENT OF NEW EQUIPMENT AND PROCESSES IN MICROLAB

· SUSS

PMC150 PROBE STATION

I evaluated and specified multiple potential site

locations in preparation for the newly acquired cryogenic probe station from

Suss Microtec. At least 5 different sites were considered. Autocad layouts of

the rooms, facility requirements, and equipment move logistics were presented

to Professor Nguyen and members of his group. Quick-glance table comparisons

were also submitted with final recommendations. I worked with The Cory Hall

Machine Shop concerning work request estimates as well as logistics of prep

work, receiving, transferring, and install of the probe station. The equipment

was successfully sited in 355 Cory. Post-install I helped to write and format

an operations manual that is to be posted online for upcoming users.

· PICOSUN ALD

I worked

to prepare and verify compatibility between the former RTCVD equipment load

lock and the newly incoming Picosun atomic layer deposition tool. Making use of

the RTCVD load lock mechanism ultimately provided a substantial cost savings

that would have otherwise been associated with the new ALD equipment.

· ALN

PIEZOELECTRIC ALUMINUM NITRIDE

The piezoelectric grade aluminum nitride sputter

equipment was upgraded to 6inch substrate compatible equipment this year. I

designed a silicon pocket wafer process flow for fabrication of a special wafer

carrier to provide continuation of 4 inch substrate processing at the tool. The

pocket wafer design allows wafer to rest on a silicon pocket eliminating the

need for adhesives. The process flow consisted of a dual mask exposure, with

front-back side alignment contact lithography. I worked to fabricate several of

these pocket wafers to meet the upgrade deadline. The carriers are currently

available for use with ALN.

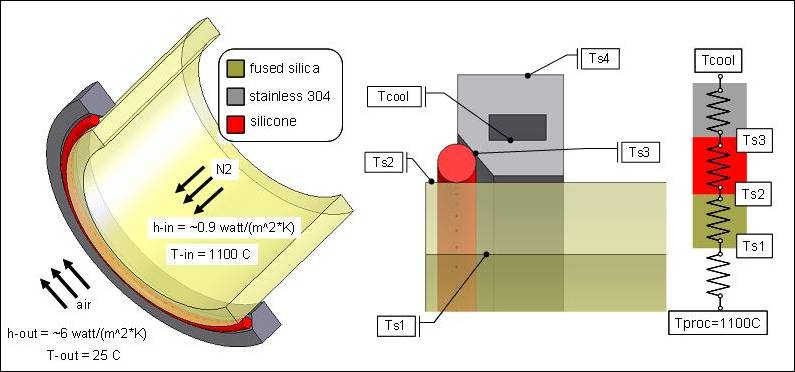

· TYSTAR 15

I performed heat transfer analysis for verification

of a new water-cooled flange seal design augmentation at Tystar15. The

functional requirement for a silicone o-ring to withstand 1000 deg C furnace temperature

(methylsilane + H2 gas) was first established. I built a one-dimensional

conduction/convection model using Mathcad software, and thereafter determined

theoretical internal furnace convection coefficients. The results of the model

showed that the water cooled flange would cool the o-ring suitably. The flange

was installed at Tystar 15, and runs were made with success.

Figure 1

LEFT: Cross section of Tystar 15 furnace tube with

temperature conditions and coefficients.

RIGHT: Detail of surfaces analyzed and respective

thermal circuit model.

II.

SUSTAINING OF EXISTING TOOLSET &

SUPPLEMENTARY PROCESS DEVELOPMENT IN MICROLAB

· CENTURA DEEP SILICON ETCH

Much

effort and progress was made this past year with the 6 inch compatible DRIE chamber.

This equipment is expected to serve as “work horse” for 6 inch war DRIE

processing in the new Marvel Lab. Following observed process result anomalies

in late 2007, I performed work to systematically evaluate independent

components and sub systems as they related to process.

Gas Delivery

One

concern was that the C4F8 (Octofluorocyclobutane) gas was potentially

condensing to a liquid inside the delivery line. Because C4F8 has a low vapor pressure,

a condensed gas due to throttling though the mass flow controller was not

inconceivable. Cooling, and consequent condensation would hypothetically be

caused by a Joule-Thomson effect. Using a special generalized residual enthalpy

correction chart calculation, a temperature drop across the MFC was estimated.

The temp drop calculated from the model was ultimately too small to cause

condensation. In the course of this investigation, it was however noted that

the SF6 pressure was regulated much higher than the C4F8. A series of process

experiments showed that by lowering the SF6 regulated pressure substantial

improvement was achieved. Less black silicon notable. Thus the high partial

pressure of SF6 in a single gas delivery line may have contributed to small

amounts of C4F8 condensation.

RF Bias and Match Network

The

cathode bias was also extensively tested. I demonstrated that neither the

pulsing nor the low frequency (400 kHz) functions were working properly. The

matching network for the bias generator also became suspect. All of this

information was documented and presented to Applied Materials. Applied conceded

that the bias was not configured correctly, and what’s more the wrong type of

bias generator had been installed. A special HALO (high accuracy low output)

generator was put on order. Upon receiving the HALO, Applied service reps spent

several months troubleshooting and reconfiguring the generator to the system.

Both hardware and software were modified, and updated as necessary. I assisted

with process testing during this entire period, and furthermore provided

continuous recipe development for Labmembers that needed use of the tool. This

was performed concurrent with the aforementioned work. Eventually a proper

configuration was obtained. I worked to confirm proper pulsed bias operation,

duty cycle and period from the HALO generator. I am pleased to report all

reflected power issues with the matching network were verified as resolved.

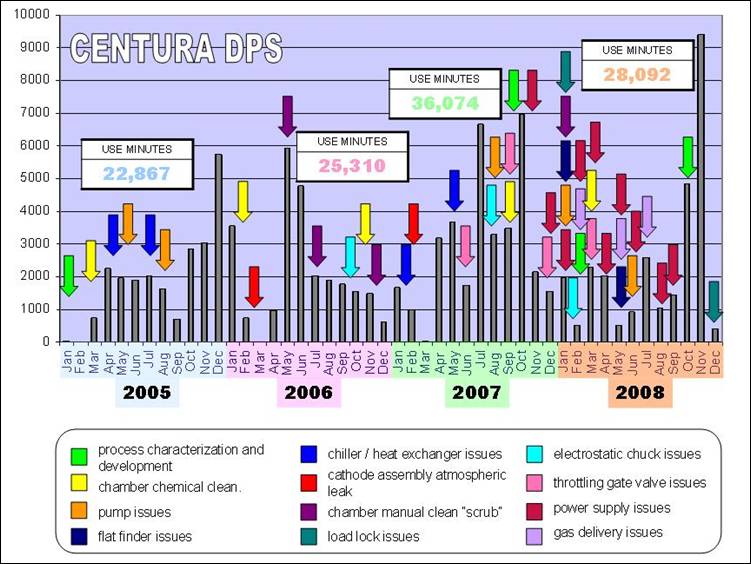

A

historical summary of DPS equipment-use vs. encountered issues may be seen in FIGURE 2. Despite the various system

issues experienced throughout 2008 with this equipment, the DPS deep silicon

etcher was still capable of providing DRIE processing on 6 inch wafers for

those labmembers with patience.

Figure 2 - Centura Use Chart vs. Problems Encountered (Updated for 2008)

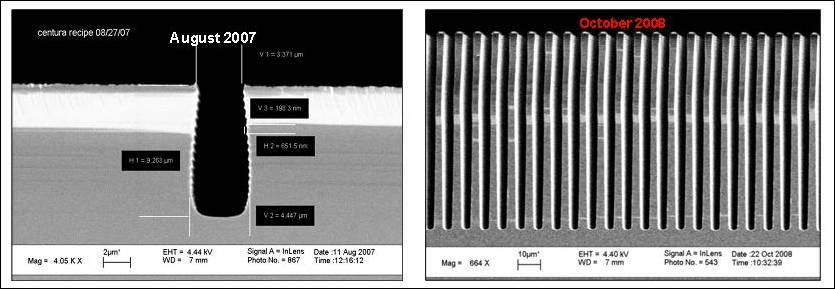

Process Characterization

The

re-characterization of the DPS deep silicon etch process followed the

resolution of all outstanding mechanical and electrical system configuration

issues. A resolution V, 16-run factorial design of experiment was conceived and

performed. Five different factors were studied in this experiment: C4F8 and SF6

flows, C4F8 and SF6 pressures, and continuous wave (non-pulsed) bias power.

Once the data from the runs was analyzed, special fine-tune process runs were

performed to achieve results for application specific recipes. Results of a

newly developed recipe are contrasted with previous recipe performance in Figure 3. The recent

recharacterization of the chamber also served as a foundation for

implementation of routine statistical process control for the chamber. Etch

rate, uniformity, and selectivity monitoring commenced in November 2008. Detailed

monitor results are documented online for public viewing.

Figure 3

LEFT: DRIE results prior to mechanical and

electrical issues being resolved at Centura.

RIGHT: DRIE process results following recent

characterization.

·

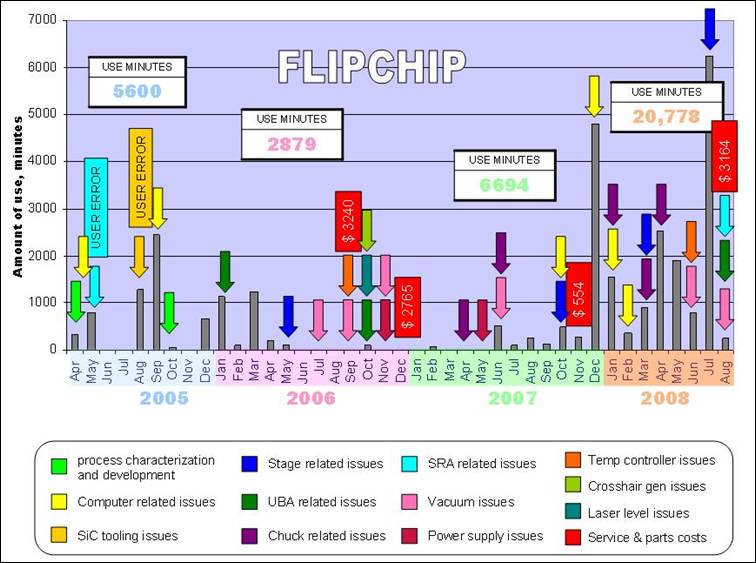

FLIPCHIP BONDER

The Suss MicroTec FC-150 flipchip bonder is a high

performance bonding tool capable of performing thermocompression and solder

reflow processing. I continued to serve as an equipment and process support

engineer on this equipment in 2008. I troubleshot issues as they arose, and

made recommendations to Microlab technical staff and third party vendors when

necessary. Regimented operations training, instated formerly, has continued to

succeed in preventing user errors with the tool. I continuously provided process

consultation on this tool. Although not without issues, for the better part of

the year, flipchip performed well for most applications.

SET (Smart Equipment Technology;

Flipchip encountered a serious stage crash in

August that eventually required third party vendor service visit. Equipment

software parameters needed resetting due to the crash. Several days following

this fix the Zerodur thermode thermocouple detached from the arm. Microlab

technical staff was able to skillfully repair the thermocouple in-house, not an

easy task. Unfortunately more independent problems followed: PC power supply

failure, corrupted DI/O PCB card, temp sensor wiring, large misplacement from

faulty N2 chip blowoff circuit, and more erroneous software equipment

parameters. Through perseverance, staff worked in team effort to solve all

these problems.

A cost / benefit analysis evaluation for flipchip

may be seen in FIGURE 4. This past

year produced the highest recharge for the tool yet. The study projects a

recoup of cumulative equipment costs (Y2005-2008) in 2009. A larger researcher

base is anticipated as reliability continues to be improved. I consider

flipchip a case example that establishes when properly managed, even the most

sophisticated systems are sustainable in an all-inclusive research environment.

Figure 4 - Cost-Benefit Study for FLIPCHIP

·

STS

STS

continued to perform exceptionally as a deep silicon etch tool for Microlab and

its labmembers in 2008. The equipment accumulated 8000 minutes of use per

month on average this past year. I continued to support operation and

processing aspects of this important machine.

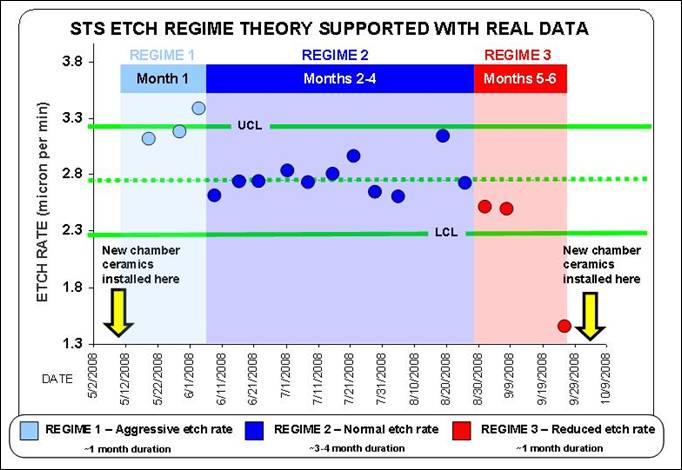

Process

I continued my efforts at educating labmembers on

the specifics of DRIE processing as needed. Aside from the routine training and qualifications on the

tool, I provided process support for researchers and staff members alike. Because

process drift with DRIE is inevitable, I served to develop and fine-tune recipes for specific

applications upon request. The main cause of process drift at STS is

thought to be carbon-rich byproduct accumulation on the chamber walls over time

(sputtered resist, passivation gas deposits, etc.). This buildup changes the

plasma chemistry, and results in a net reduced fluorine availability. Process

drift at STS occurs in cycles. Typically, Microlab’s STS chamber experiences 3

etch regimes over a six month period. The first stage follows a clean ceramics

install, and is characterized by aggressive, reentrant profile etches. A

moderately used chamber defines the second stage, most recipes in STS database

were developed for this regime. The third and final stage of the chamber is

distinguished by lessened etch rates and etch “energy”. This is due to lessened

available reactant, but recipes may still be adjusted to produce similar

results as previous. At the end of the third stage, cleaned ceramics are

installed, and the cycle begins again. The statistical process monitor instated

at STS this past year produced data that supports the theory outlined above.

Such data is presented in Figure 5.

Etch rate,

uniformity, and selectivity is now monitored at STS on a routine basis by

Microlab student workers. The information is documented and presented online

for public viewing.

Figure

5 - Etch Regime Theory Superimposed With

Real Etch Rate Data

Acquired From STS Routine Statistical

Monitor

I also

created a quick-glance process trends chart based on first order STS process

performance trends for submission to Microlab process staff. Information

contained within the chart provides concise instruction for adjusting recipe

parameters, with case examples, and presents the distinct process cycles that

the chamber experiences over a period of 6 months. In my absence the chart may

be used to fine-tune recipes as needed, something I am often asked to do.

Mechanical and Electrical Issues

I worked with STS personnel to troubleshoot and ultimately replace the

physical capacitor assembly in the coil match network. The old capacitor

assembly was shorting and causing coil tolerance errors during processing.

Subsequently, I worked to address an unexpected RF interlock display unit

failure. A new module was specified, purchased, and installed. The turbo

molecular pump and controller also failed in 2008, and I performed an

evaluation of different turbo pump configurations for DRIE processing.

Molecular drag stage, foreline pressure capacity, throughput, and by-product

build-up resistance pumps as compatible replacements were reviewed and

tabulated. This Information was consolidated into a color coded table format

and presented to lab management. Ultimately a Seiko Seiki STP1301 turbo was

successfully installed. Having the Seiko Seiki turbo at STS facilitates

maintenance, as most major etch tools in Microlab use this type of pump.

Shortly thereafter, a chamber vacuum leak was encountered, a fourth consecutive

yet independent problem at the machine. I persevered to troubleshoot and eventually

found the leak to be in an auxiliary valve on the chamber port. The valve was

replaced with success. An additional gas interlock was added to the STS this

past year after problems became relevant with labmembers attempting to bypass

recharge with the tool.

6-Inch Upgrade

The 6-inch upgrade of STS was to take place in

2008, but was inevitably delayed. A commitment to have a reliable pulsed-bias

process working at Centura-DPS before upgrading STS to 6-inch was made. Delays

at Centura, as well as prolonged issues at STS caused the upgrade to be pushed

back. All parts for the STS upgrade were acquired, and this is slated to take

place in early 2009..

· CRESTEC

I underwent training on the new Crestec e-beam lithography

system with the intention of providing process

assistance for BSAC researchers on this equipment. The system has demonstrated

capacity to write 10nm resolution features. I specified and ordered

phosphor-bronze clamps for holding dies, an improvement from “taping” small

samples to the chuck. I also had the opportunity to troubleshoot and solve a

minor issue with the equipment while several Microlab technical staff were on

scheduled leave. This kept the machine up and available for processing.

III.

PROJECTS

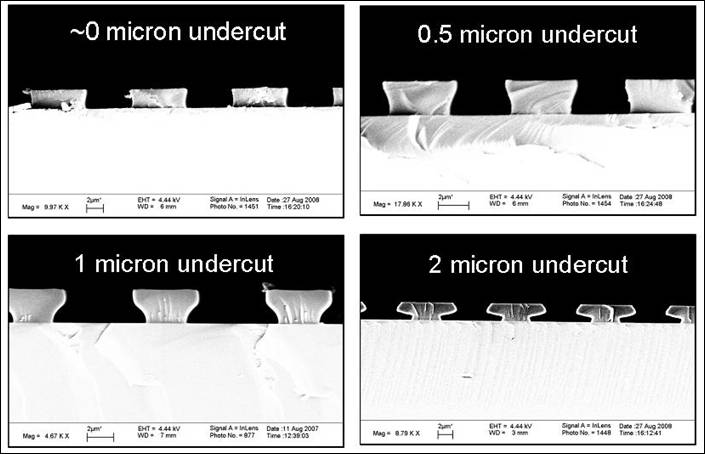

· LIFTOFF PROCESS CHARACTERIZATION

I

investigated multiple standard and non-standard lift-off methods previously.

This project’s main goal was to study, verify, and define a baseline lift-off

process for use by a large group of researchers with a broad range of

conditions. A bi-layer process was ultimately selected as a preferred means of

performing liftoff. This preferred method uses standard stock resists, and no

special chemicals are required. The preferred bi-layer method also uses

standard recipes on the spincoat tracks, thus facilitating processing.

Following the online documenting of this process flow, labmembers began to

register complaints that the bi-layer method had flaws. One claim in particular

was that the flood exposure was not necessary and even detrimental to the

liftoff profile. Rather than let rumor and superstition rule the lab

environment, I addressed such by performing a follow-up Box-Behnken response

surface study in the attempt of providing elucidation on these claims. The

design of experiment consisted of 15 runs. Flood exposure intensity, critical

exposure intensity, and develop time were investigated at three different

levels respectively. The results of the experiment gave insight, perhaps even

more than originally anticipated. It was found that a flood exposure contributed

largely to decreasing variability in liftoff profiles. Thus, the experiment

predicted that those labmembers skipping the flood exposure step would

invariably not be happy with the results. The original process publication was

authenticated, in that a proper flood exposure was an important step in the

process. All of this information was

documented for online viewing and furthermore reported at the bi-annual BSAC

industrial advisory board meeting.

Figure 6 - Demonstration of the

Pictures show photoresist profile on silicon.

Insight taken from the Box-Behnken response surface design performed.

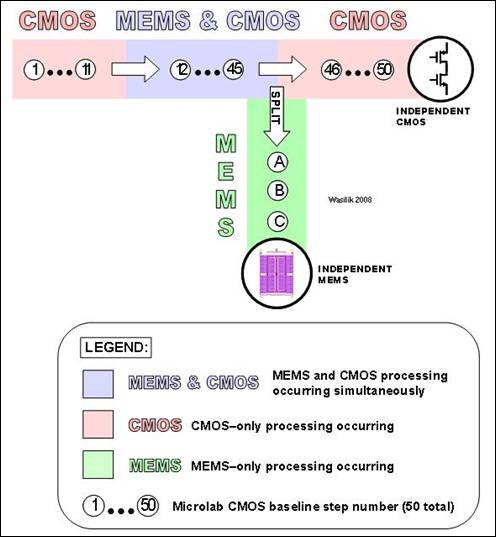

· CMOS BASELINE EXTENSION FOR MEMS PROCESSING

This project involves the fabrication of a MEMS

electrostatic mono directional displacement device by using Microlab’s CMOS

baseline. The project was unfortunately placed on the back burner for much of

2008 due to other high priority issues in the lab. I am pleased to report

however that a final mask set for the devices that measure Young’s modulus was

designed and completed. The steps remaining to prove functionality of the

device involve depositing a test material, in this case poly silicon, then patterning

and releasing the device. Future structures, already made with the CMOS

baseline process, will have the capacity to measure fatigue and rupture

strength. Note the structures do not have to be made of poly silicon, such is

for verification purposes only.

Figure 7 - Parallel Processing With “

Steps

1-50 to make CMOS, MEMS “split” occurs after step 45.

Steps

A, B and C then take place to make MEMS devices.

Note

final MEMS devices are standalone, not integrated with CMOS.

IV.

OTHERS

· BSAC

INDUSTRIAL MEMBER VISIT

I co-hosted BSAC members Starkey for one full day

in August 2008. A presentation on Microlab process capabilities, discussion,

and detailed lab tour was provided.

· GRAPHICAL

DISPLAY OF INFORMATION

I worked

to improve my skills with graphical display of information. Examples are

included in this report.

· MARVEL LAB CAD LAYOUTS

Being a

staff member proficient with AutoCAD, I organized and formatted multiple

AutoCAD drawing layouts of the new Marvel Lab for plotting and reference.

· MICROLAB

TOURS & BSAC LUNCHEON SEMINARS

I served as default host for the weekly BSAC lunch seminar. I

also provided Microlab tours for current and potential BSAC industrial

members as necessary.

· PROCESS CONSULTATION

I assisted BSAC labmembers with process questions

regarding DRIE, various plasma etch, various wet etch, molecular vapor

deposition, HF vapor release, SEM instruction, wafer bonding, mechanical and

optical profiling, IR camera microscope inspection, thermocompression bonding,

contact lithography, flipchip bonding, and liftoff during the course of the

year.

V.

FUTURE GOALS

· CMOS BASELINE EXTENSION FOR MEMS

PROCESSING

I will complete the fabrication and

testing/verification of the electrostatic displacement microactuator that was

fabricated in the Microlab’s CMOS baseline process. A working device will have

the capacity to test Young’s modulus of different materials. A known test

material (such as polysilicon) will be processed with the devices to confirm

functionality.

· MARVEL LAB

MOVE

I will be heavily involved with the move to the new

lab. During the past year I have worked to successfully instate process

monitoring on “high profile” equipments. Such will serve as a baseline for

process start up for these machines when in the new lab. Further detailed

baseline tests on equipments under my responsibility will also be required

before their move. I will furthermore perform mechanical/electrical design with

respect to the move as necessary.

· PICOSUN

I will perform a design of experiment

characterization for this new equipment, and create a baseline test prior to

its move into the new lab.

· SUSS

PMC150 PROBE STATION

I will continue to actively support this

BSAC-specific important equipment.