MEMORANDUM

To: Katalin

Voros, Operations Manager

From: Sia Parsa,

Process Engineering Manager

Date: 23 January 2009

This

memorandum documents process engineering activities for the calendar year 2008.

Last year, I supervised the process engineering group comprised of 4 process

engineers, including; one MEMS-Exchange engineer, as well as the baseline

research associate, and average of three lab assistants (undergraduate

students) and one graduate student researcher in the Microlab.

It was a

very productive year both in terms of maintaining the operation and generating

record amount of revenue through staff service/support of BMLA members and

other universities. These activities along with installation and

characterization of new tools in the Microlab kept staff challenged and very

busy throughout the year. There were total of 10 training sessions (2 days

each) offered by staff on the new Crestec E-beam writer machine. The Picosun

ALD machine, our other new tool in the lab required direct staff involvement

during the acceptance and process development phase. SVG coater 1, 2 and 3

tracks were also converted to increase our six-inch capability, while still

offering four-inch processing in the Microlab. A complete rebuild of the

six-inch developer track greatly improved mechanical performance of the tool,

also increased its memory storage to save up to 99 recipes (old version could

only save up 9 recipes).

Last year,

the last and final version of the MEMS-Exchange runs under the Plastically

Self-Aligned Micro-Mirrors project was completed. This run yielded much

better than the previous runs, partly because of the suggestions made by staff

at the conclusion of the second run (R3506), as well as cumulative knowledge

gained through the design and processing of previous runs.

Process staff was involved in many other tasks including

preparation for the new lab. The following summarizes Process Engineering

activities for 2008 (last) year.

II.

EQUIPMENT UPGRADE & NEW INSTALLATIONS

Crestec e-beam Lithography

System (New)

Last year, a High Resolution Electron Beam Lithography System was

installed in 197 Cory Hall. The new

Crestec e-beam writer, model CABL-9000, successfully passed the qualification

test in February (10nm isolated features and <20nm stitching accuracy over a

50 micron square field). The inspection

of tool by equipment staff at the vendor site and receiving basic training on

the tool helped the smooth transition of the tool into our lab. The Crestec

engineers were also very helpful and courteous, quickly offered the first round

of training to our designated staff, Kim Chan, and selected members. Kim then

promptly held the first training session for other members in late February,

and since then a total of ten 2 -day trainings have been completed. This

enabled around 30 qualified members on this rather sophisticated tool in the

Microlab. The Crestec manual is now at

its third revision, with base processes listed for different types of PMM

resist (different molecular weight). PMMA resist is a great alternative to a

much more expensive and exotic resist/s recommended and used by Crestec

(ZEP-520A positive resist from ZEON Chemicals or negative tone

inorganic Hydrogen silsesquioxane (HSQ) are much more costly and are not needed

for most of our applications).

Picosun ALD System

A new Picosun Atomic Layer

Deposition (ALD) system, made available through a grant by Professor Clark

Nguyen was quickly installed and qualified in the month of November. The new system comprises of a wafer loader

station, a deposition chamber, a

source cabinet with associated electronics and MFCs, all of which are

controlled by the Picosun software installed on a PC that is connected to a

user-friendly touch control panel. I worked closely with the field engineer at

the initial stages of the installation and acceptance of the tool. The tool

passed the acceptance test in November (490Aº thick film deposited at less than

three percent non-uniformity). Jimmy was assigned the task of receiving

additional training and qualifying members on the tool. There are currently two

metal sources available on this ALD machine.

Trimethylaluminum Al (CH3)3 is the source used for depositing aluminum

oxide and Tetrakis Isopropoxide (TTIP) used for Titanium oxide deposition. The

titanium oxide process is a somewhat slower process; 1/4 of the deposition rate

as compared to the aluminum oxide currently at 1Aº/cycle deposition rate. The

task of qualifying and process development has required close collaboration

between staff and Microlab members who seek their special application processes

on this tool. Jaeseok Jeon and Vincent Pott investigated electrical quality of

200Aº thick aluminum oxide film deposited on P-type substrates. Chemical

resistance and MOS capacitance performance of aluminum oxide dielectric was

measured (P-substrate/Al2O3/AL stack), results were as per follows:

-

No

significant film thickness loss in HF vapor (up to 21 minutes exposure was

attempted).

-

Significant

film loss in 5 minutes of BOE/piranha (~18.6 nm out of 20 nm original film

lost).

-

No

significant change of the film thickness after applying 5 minutes of RTA in N2

ambient.

SCA measurement of the film after the RTA:

Nsc = 4.70E14

Qox = -1.97E12

Dit = 3.37E11

Qfb = -1.78E12

Ts = 45

n = 1.7

-

The I-V curve of NMOS capacitor

structures with different dielectric thicknesses were also measured on various

sites on the wafer for 0 to 2volts bias condition. Following data is from the

center location:

A. NMOS capacitor (300 nm Aluminum/20nm aluminum oxide/p-type

substrate)

Maximum leakage current at 2 volt bias = 28.35 nA/cm2

Minimum leakage current at 0 volt bias = 2.1 nA/cm2

B. NMOS capacitor (300 nm Aluminum/3nm aluminum oxide/p-type

substrate) :

Maximum leakage current at 2 volt bias = 204 nA/cm2

Minimum leakage current at 0 volt bias = 0.13 nA/cm2

Shallow Junction Diffusion Process

There was a need for a very shallow p-type junction requested for

the MEMS-Exchange run R4521. I was able to have the customer at MEMS-Exchange

pay for the SRP work that was needed to target their desired shallow junction

depth (relative to our standard process). They originally asked for 1um, but

later opted to go with XJ ~1.9 µm. Diffusion process was performed

with three groups of wafers at three different process times in Tystar14,

14SB+O2 recipe at 1050ºC. Drive in was

fixed in Tystar3 at 900ºC for 30 minutes followed by 5:1 BHF for 15 minutes to

strip the top oxide. This was a valuable free of charge analysis, yielding

interesting results at 0.5, 1 and 2 hrs diffusion times that had not been

characterized earlier. We had always

aimed at MEMS applications and deep junction depth in the past. This was a

useful additional data point that complemented our old data set generated a few

years back.

Junction

depth at three diffusion times

0.5 hr

diffusion process: XJ= ~

0.88

1 hr

diffusion process: XJ=

~1.6 µm

2 hrs

diffusion process: XJ

=1.9 µm

Six-inch SVG Developer Upgrade

After many years of patiently waiting for the SVG developer

upgrade to eliminate the leaky stationary nozzles at this station, the

opportunity arose in the summer at a reasonable price tag. The process group

went out of their way to accommodate the change. I worked through weekend of

September 13th to make sure the tool would have minimum downtime

during its upgrade. A basic DUV develop process was then made available that

Saturday. Other developer recipes were soon released for I-line and G-line

resists, as well. The retractable arm has made the tool much more reliable and

trouble free.

III.

PROCESS

DEVELOPMENt, sustaining &

IMPROVEMENT ACTIVITIES

New Processes

-

New processes were released on all of

our new equipment installations (Crestec e-beam lithography, Picosun ALD and

six-inch SVG coat and develop machines).

-

Low stress silicon carbide process was

tested by Daniel Queen in Tystar15. This process uses DCS, DSB and NH3 gases

with a deposition rate of around 53 nm/min. A full report is available at the

Microlab web site, following link:

http://microlab.berkeley.edu/text/processreports/SiC.pdf

-

Hot Aluminum process was tested by our high

school summer intern, further refined by Daniel Queen, a Two-Step Hot

Aluminum (TSP) process in the Novellus m2i machine. A high temperature

treatment (500ºC) is used to reflow an aluminum film that has been deposited at

low temperature (300ºC). This process improves the metal step coverage inside

the contact and via holes, enabling more advanced technologies. Please note;

the initial temperature of the wafer is critical for good reflow of the

deposited aluminum film. To ensure that the wafer is at a suitably low

temperature, the Ti adhesion layer station needs to completely cool (~12 hrs

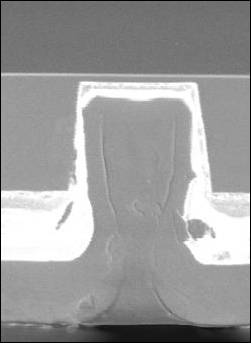

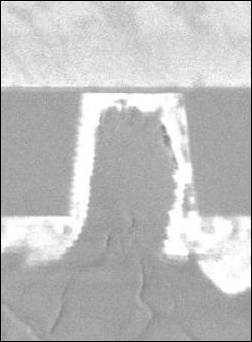

from 300°C to 50°C) prior to starting deposition. The SEM pictures of 2 µm

contact holes in Figure 1 show much better contact coverage by the hot aluminum

process (Figure 1b), as compared to the standard aluminum sputter process

(Figure 1a).

Figure 1 - Cross Sectional SEM of a 2 µm Wide and 2 µm Deep

Contacts

(a)

Cold Aluminum Poor Step Coverage

(b)

Hot Aluminum Process Improved Step Coverage

Current Processes

-

Due to a long lead time associated with

DUV resist manufacturing/delivery, resist usage was closely monitored by

process staff to ensure no shortage of resist would occur. BARC and other

support material were also monitored and ordered by the process staff in a

timely manner. Process group also

investigated a BARC batch problem by contacting vendor and running experiments

on the track (different bake time/temperature and delay time).

-

A set of parylene experiments were

conducted by Attila for our BSAC engineer (Matt). A linear relationship between

the thickness of deposited parylene and the amount of dimmer used to deposit

such film was established.

Parylene-C

thickness (µm) = 1.339 X amount of C dimmer mass (g)

Parylene-N

thickness (µm) = 0.4086 X amount of N dimmer used (g)

Equipment Support

Wafers Saw

-

Daniel Queen, our graduate student

researcher, experimented with six different types of blades (various

length/width) aimed at selecting one possible solution to all our silicon

dicing needs, including double bonded six-inch wafers (the thickest possible

stack used in the Microlab). I provided Daniel with different type of blades

and some bonded oxide wafers that had been prepared earlier. He quickly settled

on the Keteca K3T20L45 blade. The wafersaw manual was updated with the

following specifications:

Keteca,

P/N K3T20L45 blade specification:

kerf (width of cut) = .45 microns or .0018”

Maximum depth of cut = 1.140 mm or .045”

Maximum

Cutting Speed: 3 mm/se

ASML

-

The ASML reticle stage was severely

damaged by the poor quality of an incoming reticle that was purchased from an

outside vendor and used by one of our Microlab members. The original cost of

the repair estimated at $122,571.33 was negotiated down to $90,811.73 (including

tax) through 35% exchange credit and an additional discount that was approved

by ASML management. I worked very closely with the ASML to negotiate the cost

and expedite the repair. ASML Company took about a month to make the

replacement parts available to us, and more than a week to install it on our

tool. Rosemary vigorously pursued the financing part of the deal and was able

to get the campus Risk Management office involved with a third party assessor

assigned to our case. Evan and I worked closely with the assessor, provided him

with necessary information, access to the tool and digital pictures for the

appraisal. I am delighted to report that

we were able to recover most of the repair cost ($85,317) through campus

insurance. Great collaboration between

all parties involved, getting us back to normal in a relatively expeditious

manner, and considering the enormity of the damage involved. Bob and the

machine shop (Ben) later provided us with a nice fixture (reticle template)

that can be used to check quickly and accurately the size and shape of an

incoming reticle. I updated the ASML manual for all qualified members to

inspect their incoming reticles on this fixture, so that there will be no

chance of such a mistake ever happening again!

Xetch

-

The equipment engineer in charge of the

Xetch, Joe requested that we set him up with a quick method of checking the

health of the XeF2 machine (Xetch), after repair or in case of a problem

report. I proposed that we pattern and

etch 10 oxide wafers with different size structures to baseline the Xetch etch.

The following steps were taken to generate the test chips needed for the Xetch

monitoring:

-

Laszlo designed a die with lines/spaces

of various size/density for this test mask.

-

Kim patterned (ASML) and etched

(Centura MxP+) eight oxide wafers (280 nm oxide).

-

Wafers were then partially diced, so

that the test chips can easily be snapped off.

-

Resist was then removed from these

wafers so that the patterned oxide can be used as a hard mask for silicon

etching and the ASIQ machine to determine etch depth/rate.

Tylan17

(LPCVD LSN Process)

-

Excellent troubleshooting was performed

by equipment (Danny) and process (Jimmy) staff on a major process pressure

issue reported on Tystar17, early October.

Many steps were taken to narrow down the root cause of the failure,

including process check at different stages of the repair that ultimately

brought the tool back on line. The rear of the tube was severely choked up by

hardened material; therefore, the tube had to be replaced. Process ultimately

checked out and the tool released to Microlab members.

Lab Manual Write-Up, Process Monitoring, and Qualification Tests

Last year,

process, BSAC, and Baseline engineers updated all the lab manual chapters

assigned to them with revision dates older than 3 years (listed below).

Microlab equipment engineers and technology manager, as well as selected number

of Microlab members took part in this overall effort to keep our lab manuals up

to date.

New and

Rewritten Chapters

Chapter 1.3 - New MOD 37 - Processing

bottom Anti-reflective coating (10/08).

Chapter 3.3 - Complete rewrite of GCA

pattern generator chapter to the new format (08/08).

Chapter 4.24 - Total rewrite for a

standalone SVGCOAT6 chapter (09/08).

Chapter 4.26 - Rewrite of the SVGDEV6 chapter post hardware

upgrade (11/08).

Updated

Chapters

Chapter 1.2 - Added a note in chemistry

safety section of the Microlab safety rules (11/08).

Chapter 1.5 - CMOS process flows posted

for 6" substrates (2008).

Chapter 1.6 - Edited wafer substrates

chapter (08/08).

Chapter 1.8 - Updated equipment list on

4" &6" tool compatibility chapter (05/08).

Chapter 2.2 - Minor changes made to

Tystar and Lam rework chapter (07/08).

Chapter 2.3 - N2 flow-meter procedure

added to Sink3 chapter (09/08).

Chapter 2.4 - Hot plate safety notes

added to sinK4 chapter (11/08).

Chapter 2.5 - Updated the sink5 chapter

with current information, no HMDS bubbler (08/08).

Chapter 2.6 - Removed obsolete

references, expanded on sink6 protocol section (09/08).

Chapter 2.9 - Changed the purpose and

processes allowed in sink9 (09/08).

Chapter 2.11 - Added bases to the list of

chemicals that can be aspirated in sink432A (09/08).

Chapter 2.14 - Updated Tousimis CPD chapter with schematics of the plumbing (10/08).

Chapter 3.1 - Updated plotter

info/command lines in sections 2.4.1 in

CAD chapter (03/08).

Chapter 3.2 - Reviewed and made minor

changes to GCAWS2 chapter (03/08).

Chapter 3.8 - Few additions and updated

CMOS Baseline Test Chip chapter (03/08).

Chapter 4.0 - Minor editing of the

general resist parameter chapter (04/08).

Chapter 4.11 - Added

procedure for inspection of incoming reticles to ASML chapter (04/08).

Chapter 4.13 - Clarification

of the operation throughout the GCAWS2 chapter (07/08).

Chapter 4.16 - Modified

Subsections 9.9.1 and 9.9.2 of Quintel Mask Aligner chapter (07/08).

Chapter 4.17 - Added 10.2.2.15 & modified 10.3.1-10.3.6 in JEOL 6400 chapter (10/08).

Chapter 4.18 - Removed mark-ups and added

them in the content of Crestec chapter (11/08).

Chapter 4.21 - Separated and revised the

SVGCOAT1 chapter post 6” conversion (08/08).

Chapter 4.22 - Separated the SVGCOAT2

chapter, which has stayed 4-inch (08/08).

Chapter 4.23 - Revised the SVGCOAT3 coater

chapter post 4” conversion (08/08).

Chapter 4.28 - Modified section 9.1 of the

Matrix 106 with additional information (12/08).

Chapter 4.30 - Added safety sentences about

the hot plate in Spinner1 chapter (11/08).

Chapter 5.1 - Edited subsections 8.1.1,

8.1.2 and 9.5.11 of the Tystar1 chapter (03/08).

Chapter 5.9 - Deleted references to

section 9.2.7 and 9hstnbya recipe in Tystar9 (03/08)

Chapter 5.11 - Renumbered Section 5.10 and Inserted new Section 9.2.3 for Tystar11 03/08).

Chapter 5.20 - Minor changes made to

Tystar20 chapter (07/08).

Chapter 5.30 - Updated gas sources and

oxidation recipes used in the MOS furnaces (10/08)

Chapter 5.31 - Changed all references to

Heatpulse 2, also added pictures (03/08).

Chapter 6.02 - Revised section 8.1.2 and

10.4 and fault recovery in Novellus chapter (04/08).

Chapter 6.03 - Deleted Pt target no longer

available for the Randex machine (01/08).

Chapter 6.04 - Updated the CPA chapter with

clarification of operating instruction (07/08).

Chapter 6.07 - Define power density for

ITO, dielectric (W/cm2) in Edwards manual (12/08).

Chapter 6.08 - Deleted 6.3,

modified 8.4 materials restrictions in AMS manual (05/08).

Chapter 6.12 - Added section 10.1 about

vacuum system luck-up in Veeco 401 (03/08).

Chapter 6.14 - Added notes in subsections

5.08 and 9.17 of Edwards EB3 manual

(09/08).

Chapter 6.23 - Minor change made to the

AMST Molecular Vapor Deposition manual (12/08).

Chapter 6.29 - Minor change made to Oxford2 manual (07/08).

Chapter 6.30 - Updated PQECR manual to include

silicon nitride, a-Si process (12/08).

Chapter 7.0 - Updated lam etcher

overview chapter with minor changes (07/08).

Chapter 7.6 - Added subsection 9.3.5 in

Centura MxP+ (06/08).

Chapter 7.8 - Updated STS manual with

location of turbo controller (09/08).

Chapter 7.13 - Reviewed and added anecdotal

information to XeF2 manual (04/08).

Chapter 7.15 - Added section 8 to HF vapor

manual (11/08).

Chapter 8.04 - General probe station

chapter was reviewed and checked out (05/08).

Chapter 8.11 - Extended the Alpha step

specification and added surface roughness (10/08).

Chapter 8.13 - Minor changes made to Wyko

chapter (05/08).

Chapter 8.21 - Minor changes made to

Reichert chapter (08/08).

Chapter 8.32 - Troubleshooting guidelines

added to Sopra manual (03/08).

Chapter 8.44 - Updated section 6.2 of the

X-Ray diffraction machine (09/08).

Chapter 8.54 - Updated file transfer

procedure on contact angle machine (09/08).

Chapter 9.00 - Added KS-Aligner table to

Bonding tools overview chapter (06/08).

Chapter 9.4 - Formatted the Westbond

wirebonder chapter(03/08).

Chapter 9.6 - Clarification on operating

procedure for the dicing saw chapter (07/08).

Chapter 10.1 - Clarification on operating procedure in the CMP chapter (07/08).

New Process Reports link

I initiated a

link for process related reports, which could eventually centralize process

reports/information for general use. This way process related development

work/reports are immediately visible in the process panel of the Microlab web

site.

Process Monitoring,

Equipment Training, Member Qualification, and Test Grading

Last year o

A large

number of equipment qualification was performed this past year, written test

(graded), and oral tests were given by staff for number of tools. The BSAC and

baseline engineers also provided support in the DRIE etch, metrology, and CAD

layout/ mask making areas. I assigned superusers on various tools and helped

administration staff reinstate some of our members on their expired equipment

qualification.

New lab

Support

Process

staff provided all the requested information to Dr. William Flounders, our

Technology Manager to plan ahead for the new Marvell lab. We submitted an excel

sheet outlining our current storage

inventory, sink layouts for the new lab, as well facility requirements for each

equipment migrating to the new lab. The

facility requirements for each tool on the list was generated by the equipment

engineer in charge of a particular tool, and compiled by Attila.

IV.

process Staff Supervision,

TRAINING & OTHER SERVICES

Staff Supervision: I Continued my supervision of process/MEMS-Exchange engineers, one

baseline assistant specialist, as well as one graduate student researcher (GSR

25%), and three undergraduate assistants working in the process group. Process

staff yearly appraisals were submitted on time, before the September 1st

deadline. Last year, I also mapped all

of our job titles to new categories defined by the university.

Promotion and Awards: Last year Kim received her 30 years service award for many

years of consistent and reliable service in the Microlab. Chris Zhao also

received the SPOT award. Chris has provided excellent and beyond the call of duty

service during his 2 years of working as a lab assistant in the Microlab. He is

starting the graduate school this year and will continue working in the

Microlab as a Graduate Student Researcher.

High School interns: Microlab was able to

continue our 6 year old summer internship program with two new high school

students; Kelsey Brokaw and Alice Wong. Jimmy Chang (senior process engineer)

and Daniel Queen (PhD candidate) provided mentorship and helped the interns

conduct process optimization work in the Microlab. The results of their

experiments were presented to the Microlab staff and guests at the conclusion

of their summer internship, as follows:

-

Kelsey Brokaw conducted her work in the

CMP arena. The effect of different process parameters on the oxide polishing

rate and removal uniformity were examined. She determined that both down

force and backside pressure had significant impact on etch rate and

percentage of the film non-uniformity; she developed an optimized recipe that

had high back pressure and down force. Kelsey also concluded that we could

perhaps extend the life of our polishing pads, as the old pads still had some

life in the them.

-

Alice Wong compared the hot and cold aluminum

processes in the Novellus m2i system. This project gave her the opportunity to

use various equipment including sinks,

furnaces to grow an oxide layer that was then patterned and etched (ASML)/Centura MxP+) to create via holes for her experiment. She

concluded that the two step hot aluminum process provides better via step

coverage than the standard sputter aluminum process. Addition of 500Aº Ti

underlayer as an adhesion (glue) layer further enhanced step coverage by

capillary action that helped draw down

the aluminum inside the via holes.

Microlab, EE143: Process staff

continued their service/support of the EE143 lab by ordering new furnace boats,

and supplying the class with their chemical needs, and helping TAs with their

poly/oxide runs.

Member advising, Help/Support of Other Universities, Institutions

-

Helped a colleague from University of

Arkansas with her MOS and non-MOS cleaning protocol questions, Input

gases for a PECVD process and percentage of SiH4 in Argon was also recommended

along with a basic recipe for her PECVD oxide process.

-

Helped colleagues and graduate students

at Stanford with their process/equipment questions; discontinuation of LDD26W

develop both here and at Stanford prompted common interest. Their question

regarding a viable Cr etch was promptly answered with available etch rate data

and a Cl2 + O2 based recipe. There was also an interest in the recipes

currently used for aluminum nitride etching at our site. The information

regarding the lam3 AlN etch recipe with double the amount of Cl2 and turning

off the N2 in the main etch step was forwarded as a good starting point to

develop their AlN etch recipe. SCA and

CV plot questions were also answered by sharing our method of pass/fail

criteria and the upgrade performed earlier, as a recommendation for their tool.

-

Held weekly meetings with process

staff, discussing Microlab issues.

-

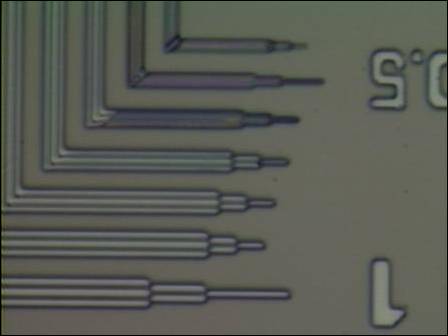

We helped Michael Helmbrecht with his

G-line exposure feasibility question on our six-inch I-line stepper (GCAWS6).

Marilyn ran G-line resist coated wafers through this stepper and was able to

resolve 0.7 µm G-line resist lines at

1.0 second exposure time. This was good news for us too, as we can basically

phase out our 4” GCAWS2 stepper, when we move to our new six-inch Marvell lab.

I also helped Michael develop a Mix&Match process between GAWS6 and the

ASML stepper that addressed his non standard die size, and required a few

tricks to get the target positions right (global alignment step on theGCAWS6).

Figure 2 - 0.7 µm G-Line Resist Fork Patterns

Exposed on GCAWAS6 Stepper

V.

Semiconductor Processing &

special Services

ETR Services

Last year process staff completed 17 engineering test

requests generating $33,651.97 in revenue for the Microlab. In addition to the standard

processing normally offered in the litho, etch and the diffusion areas, we

performed other types of non-baseline processes for various universities, which

included;

MEMS-EXCHANGE PROCESS service

Last year we continued our services/support of the

MEMS-Exchange program with one local MEMS-Exchange (MX) engineer assigned to

the task of processing MX runs in the Microlab. These runs generated $18,269.10

in revenue for the Microlab. Attila Szabo, our MEMS-Exchange engineer

successfully completed the third and final version of Professor Lewei Lin’s MX

run in November (R4119). This run incorporated design/process improvement ideas

accumulated by the fabrication of previous two runs in the Plastically

Self-Aligned Micro-Mirrors project also utilized staff recommendation

outlined in my last 2007 annual report. Following modification were made to the

new run:

- Added more test

wafers to optimize all of our critical DRIE process steps, before

committing the product wafers.

- Added backside

polysilicon strip step (16) to the new run. We had oxide/poly/oxide

stack going into the last steps of the process in the previous run, which

somewhat complicated/compromised the backside etch process.

- The polysilicon

filled trenches on the front side were oxidized (step17) to prevent

polysilicon loss during later device etch steps (26).

- Changed the active

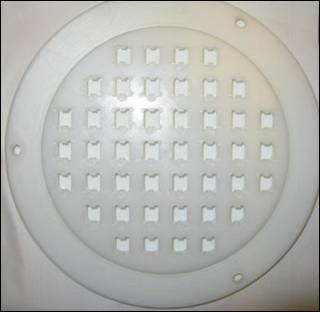

design area for better wafer mounting (wafers were mounted with their

device side down for the backside etch step). The test chip’s overall

dimensions however was kept the same, which enabled us to use the same HF

vapor clamp as was used for the previous run (Figure 3). Note: R3506 provided adequate scribe

line width in the vertical direction (Y), only.

- Increased oxide

layer for the backside etch.

- Improved (PR bake)

for backside DRIE mask.

- Instead of

cool-grease in R3506 run, we used laser-cut thermal release (Figure -3) to

mount product wafers on the carrier wafers in the latest run, R4119. This

eliminated the cool-grease contamination issues observed on the previous

run; however, presented delamination problems during the backside etch

step. Product wafers had to be remounted several times to finish this etch

step in the process.

Figure 3 - HF Vapor Clamp (left) and

Thermal Tape Laser Cut To Correct Die Dimension (right)

- Changed the design rule

for the backside etch window, which eliminated very small and/or very

large openings aimed at improving die to die etch uniformity during

the backside etch step. HF vapor

was then used to remove the buried oxide that was holding the front side

device layer in these windows, which are shown in Figure 4, below.

Figure 4 -

Images of MEMS Structures Released on Different Test Chips

Figure 4 -

Images of MEMS Structures Released on Different Test Chips

Mask Making Services

A total of 756 new masks were processed on the pattern

generator in 2008 for our internal (UCB researchers and BMLA), as well as

external customers (other Universities) listed in Marilyn's report.

Special Requests/ other Services

-

Last year, process staff helped one of

the member companies develop their proprietary process. This project stretched

our resources thin, but it was well worth the effort both in terms of the

amount of revenue generated and the opportunity to perform some challenging

process work in the Microlab. Laszlo Petho, our baseline engineer was

intimately involved with this project for the better part of the year. Jimmy lent his time and expertise in the

diffusion and etch area, developing special application processes for this

project. Bob and David Lo worked hard to have different equipment available for

each process step in this project. Marilyn and Kim also helped out with

lithography steps on different iterations of the process flow/development work.

The total amount of staff time/services charged for this project amounted to

$41,828.10.

- Process staff

fabricated few show wafers for Crestec engineers in appreciation of their

installing our new Crestec e-beam lithography system, as well as training staff

on the tool. Process staff also fabricated a show wafer that was presented to

professor King at the end of the year for her six years of mentorship and

support, as a Faculty Director of the Microlab staff supplied the Microlab

office with the regular pocket wafers, as well as poly-Si control wafers for

general use in the Microlab.

VI.

CMOS Baseline activities

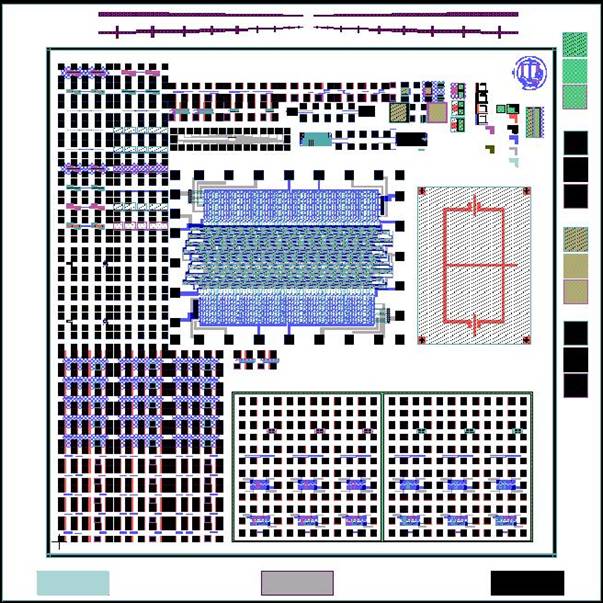

Third

Baseline Run (0.35 µm Process)

Last year, the baseline engineer Laszlo Petho,

completed our third 0.35 µm CMOS baseline run (4th six-inch run) initiated by

his predecessor Anita Pongracz. This run (CMOS180) was parked for 6 months due

to the arrival of an important BMLA project in February. Laszlo resumed the

processing work in September was able to complete and test by December. This

run accomplished our main objective of demonstrating the Mix&Match process

on the ASML/GCAWS6 steppers, as well as improved device performance by introducing the shallow trench isolation

in our new fabrication process flow. A

summary report is now available for this run at the following internet link:

http://www.eecs.berkeley.edu/Pubs/TechRpts/2008/EECS-2008-168.html

Figure 5 - Baseline CMOS180 Test Chip

VII.

REPORTS,

PUBLICATION, & TRAINING

- Last year I

attended some of the free CAL PACT classes offered on campus. This

included one day Advanced Excel, and Power Point Fundamentals, and a basic

two days Dreamweaver CS3 class on web design.

- A summary report

compiled on the third and the final Plastically Self-Aligned

Micro-Mirrors run R4119 for the MEMS-Exchange program.

- The third 0.35 µm

baseline report was submitted (CMOS180) by Laszlo Petho and Anita Pongracz

in December 2008.

- Process staff

attended BSAC IAB seminars In March and September of 2008 (1/2 day).

- Process staff

attended the Semicon West exhibition in July 2008.

- Process staff attended the Solid State

Technology and Devices Seminars on Fridays.