memorandum

To: Katalin Voros,

Operations Manager

From: Todd

Merport, Computer Systems Manager

Subject: 2008 Year-End

Report

Date: 13

January 2009

I.

Introduction

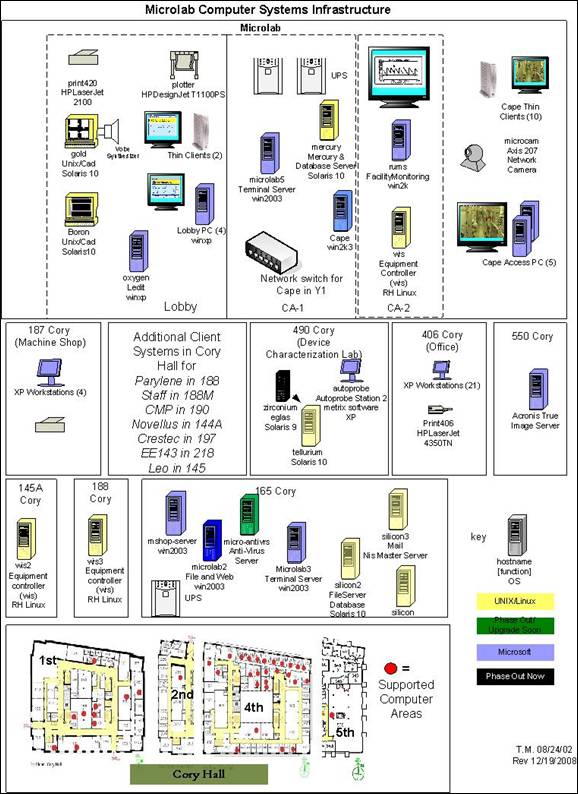

The Microlab Computer Group integrates, develops, installs,

and maintains computer systems that facilitate efficient operation of the

laboratory. Eighty five computers

are in service that run on Windows (XP, Server), Solaris, and the Linux

operating systems (see Table 1). These systems support activities of 450 members

in the Microlab. Software running on these systems includes web servers,

database servers, terminal services, equipment control, and data acquisition.

II.

SYSTEM ADMINSTRATION

User desktop systems are setup to run Microsoft XP. Windows

2003 servers support the desktop environment. The lab terminals run Windows

terminal server (

Usual system

administration tasks include patching, backups, file-system management, account

creation, and assisting members. Some additional tasks are mentioned below

completed in 2008 are noted below:

Changrui Yin,

replaced ten user workstations. This process was facilitated by our Acronis

True Image server that has the capability of cloning one computer to another

even with differing hardware. The

True Image server has also been useful for making images of

Two systems

were deployed for the Crestec install in 197 Cory. Flat panel monitors replaced CRT’s

for EE143. A Sun T5120 server (4

Core, Sparc T2, 4GB), silicon, was purchased with a Sun Education program

matching grant. It is used as a development and backup server. This system has

four, 146GB high-speed disks setup as RAID 2 (mirror). This system has replaced

silicon that ran on an Ultra Enterprise 2 platform (333MHZ Sparc, 128MB Ram).

One of the

replaced PC’s has been re-built with Solaris X86, and it is used for

Hydra development.

A packet

filtering firewall ‘ipfilter’ is now enabled on all Solaris 10

servers and workstations. I developed rules that limit the cross-section of

these systems viewable over the internet. These rules are exclusive in the

sense that the default behavior is to block all incoming traffic. Exceptions

are then created as needed.

A lease with

Tanner Software was purchased allowing for 10 network licenses of L-Edit Mems

/w DXF (Autocad, SolidWorks) import/export and CurveTools. A license server

w/management tools is setup on the microlab2 server.

|

Function |

Platform |

Operating System |

Count |

|

||||

|

Desktop |

X86 Dell (Mostly) |

Windows XP |

44 |

||||

|

Web, FileSystem, Database, Mail, Applications |

UltraSparc |

Solaris 10 |

4 |

||||

|

Web, LabView |

X86 Dell |

Windows 2000 Server |

2 |

||||

|

Terminal Services |

Xeon Dell |

Windows 2003 Server |

1 |

||||

|

FileSystem, Web, Database, Anti-Virus |

X86 Dell |

Windows 2003 Server |

5 |

||||

|

Cad Workstation, EGLAS |

UltraSparc |

Solaris 9,10 |

3 |

||||

|

Cad Workstation |

X86 Dell |

Windows XP |

1 |

||||

|

Thin /Thick Clients |

Neoware/DELL |

Windows CE/XP |

19 |

||||

|

Interlock Controllers |

X86/Control By Web |

LINUX |

5 |

||||

|

Interlock Controllers |

Agilent 34980A |

LINUX |

1 |

||||

|

TOTAL |

|

|

85 |

||||

Table 1 - Summary

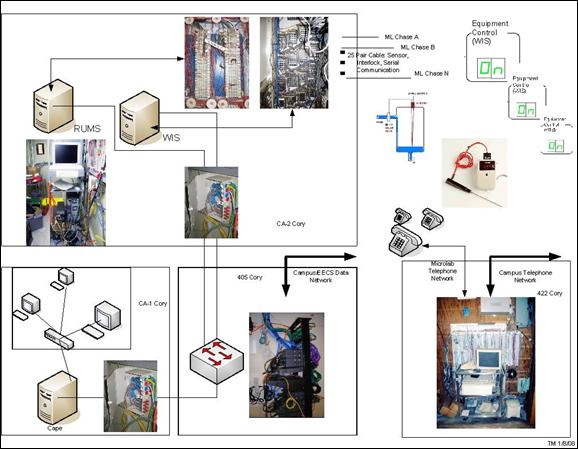

Figure 1 - Infrastructure

III.

Software

Enhancements

Equipment in 197 (Crestec) and 218 (EE143) Cory required interlock

systems controlled by the “Wand”. These locations had no wiring

available to connect to the

The Crestec system required modification of the Microlab reservation

system. Time slots had to be blocked off for Crestec personnel and then

released as needed (a subtractive reservation system). I created a script to

mass generate reservations with a variable granularity, and created a database

table to use as a mask so deleted reservations would not get re-created.

Accounting system modifications for the Crestec were made as this is a

tool with charges at variance from the rest of the equipment in the Microlab.

I wrote a program that generates accounting reports in a format that can

be uploaded to the Berkeley Financial System (BFS). This program is normally

run when an accounting period is finalized. The program parses the

‘acctusers’ and other tables in the ‘microlab’

database. Each entry has a COA entry in a single column. Some entries are valid

COA numbers and others are for bmla members or billing accounts. This BFS

upload program validates each COA and loads data accounting data from the

‘microlab’ database into a new table with individual columns for

each COA field. A Business Intelligence and Reporting Tool (BIRT) application

was designed to query and sum data generated by the BFS upload tool and export

the output to Excel. The Excel spreadsheet is then uploaded into the BFS

system. These programs save staff a considerable amount of time and prevent

mistakes when hand-entering data.

The qualify program was modified to update only the qualification date

instead of creating new records for the same piece of equipment.

Changrui added a maintenance module to the ‘pumps’ database.

This module links individual pumps to a maintenance schedule. Pumps that

require maintenance are tagged on the database forms and reports. Changrui created

new web based reports for the pumps database (in addition to the MS Access

based reports).

Changrui created the Machine Shop File Management System. This system

tracks design files by machinist, type, revision, and job number. Files can be

downloaded and uploaded. Each upload creates a new revision. Files are stored

on the machine shop server with permissions set as appropriate.

New Development

Susan Calico designed and coded the new Marvell Nanolab web site. Susan

quickly integrated the web pages into our Apache web server infrastructure and

worked with staff to determine specifications and technical requirements. She

wrote PHP programs for dynamic parts of the web site.

Mercury – Lab Management Software

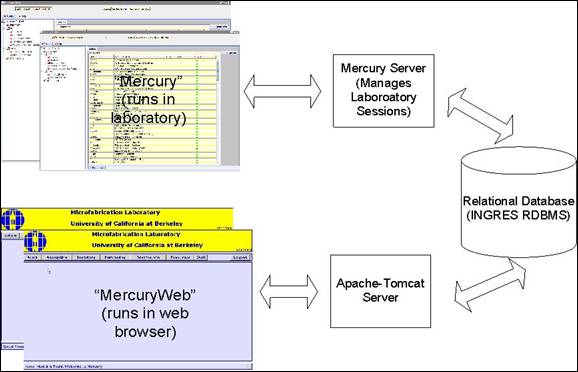

Mercury software is a multi-tiered application that uses relational database technology to capture activities in the laboratory and provide detailed reports to staff and members. Figure 2 shows Mercury’s basic components.

Figure 2 - Simplified Mercury Architecture

Mercury is undergoing testing and final touch-ups. In 2008, we

thoroughly tested the accounting system. I wrote a migration program to map

Microlab activities into the Mercury database. Thousands of Microlab equipment

and labtime activities were used as a basis to generate activities in Mercury.

Each activity triggers a series of stored procedures in the accounting system.

Individual activities, overcharges, and monthly summaries were compared with

excellent results. Olek made various fixes and modifications to the stored

procedures that handle rules for the accounting system. Additionally his accounting reports

application provided a means of quickly comparing end results for an accounting

period by member, contract, resource, and faculty.

Olek created a large number of forms and reports for the MercuryWeb and

made database changes as appropriate. These included an extensive purchasing

and inventory system. He integrated a bar-code scanner and printer system into

Mercury. Olek integrated BIRT functionality directly into MercuryWeb -- a

separate reporting application is no longer required. See the Comments section

for more details regarding the extensive development of MercuryWeb.

The effectiveness of the Mercury system can be quickly demonstrated with

its capability to allow easily changing rates and caps for classes of members

(charge rules). The Charge Rules form (in MercuryWeb) coupled with the various

tables and procedures in the Mercury database permits changes in rates, caps,

fees and specific limits for equipment, locations, or facilities. The process

to make these changes is basically filling out a form in Mercury. Adding charge

rules in the Wand entailed hand editing several tables, adding and modifying

code in several files, and re-compiling the accounting application.

Members and staff in the laboratory frequently need to track process

information. I created a parameters and parameter history module for the client

and database. Parameters can be defined for each piece of equipment and entered

during turn-on or turn-off. Parameters can be queried by various fields such as

member name, time, and range of values. Parameters are also integrated into

equipment comments for quickly viewing general comments and specific parameters

by activity. Parameters such as deposition rate, temperatures, pressure, target

metals can be defined and logged for each equipment. See Figure 3.

Additionally, I made numerous changes to the Mercury client, server, and

database. Various client classes were re-organized (sub-classed) for easier

maintenance and modification. The table that associates problems/symptoms was

re-designed. Server side code was added to support the Agilent 34980A interlock

system and the Control By Web interlock system (IP relay).

Figure 3 - Header, Tailer, and Parameters Prompts

IV.

MARVELL NANOFABRICATION LABORATORY

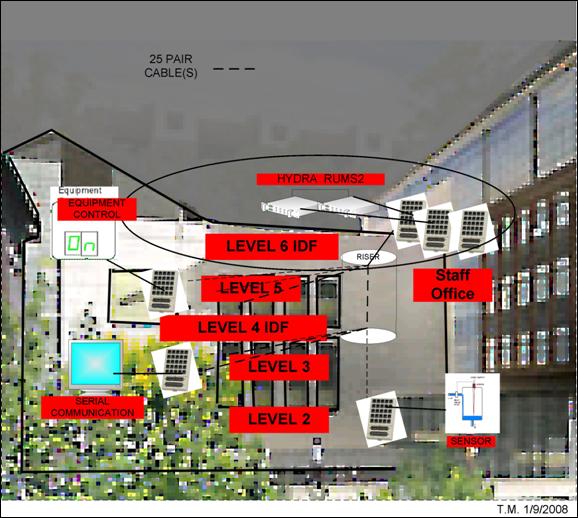

I worked with Phillip Guillory and

Bill Flounders to generate specifications for sensor, equipment communications,

and control wiring. The cabling infrastructure utilizes 25pair CAT 3 cable runs

from a central IDF (Intermediate Distribution Frame) to key locations in the

Marvell Nanofabrication laboratory. The end points will use punch down blocks

or super-mod type distribution panels. This design has worked extremely well in

the Microlab (see Figures 4 and 5).

Figure 4 - Simplified Sensor, Equipment Control Setup for the

Marvell Nanofabrication Laboratory

Figure 5 - Microlab Telecom System

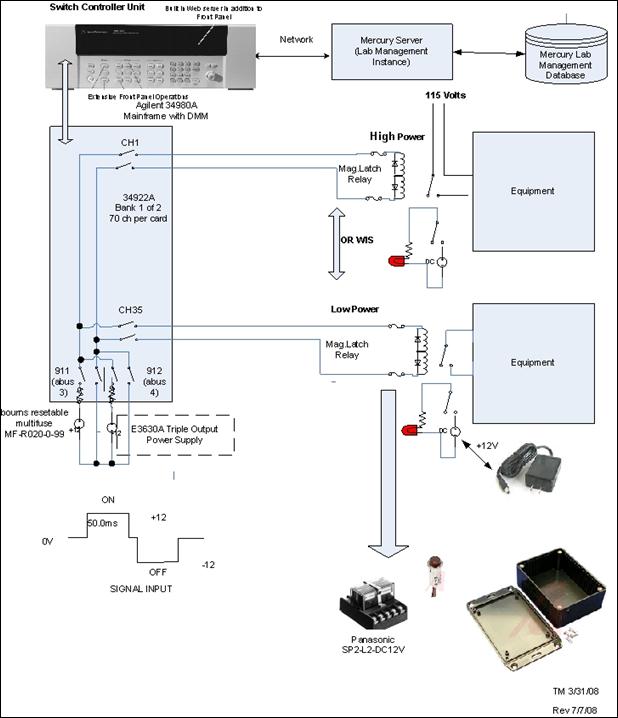

The

equipment control system for the Marvell lab (designated as Hydra) is the Agilent

34980A Multifunction Switch/Measure unit equipped with multiplexing

high-density magnetic latching relays. The system is configured to send a pulse

to an addressed channel which is connected to a Walker Interlock System (WIS)

low or high level interlock box or a Hydra interlock box (see Figure 6). Both types have magnetic latching

relays. Coil resistance from the interlock boxes can be measured on the

Switch/Measure unit to insure a proper signal path between the controller and

interlock box. The 34980A has a serial, GPIB, and network interfaces allowing

for very flexible operation. The system has hundreds of standardized commands

(well documented) that can be utilized in its operation. The software interface between Mercury

and Hydra has been written and tested.

Figure 6 - Hydra Equipment Control

V.

COMPUTER GROUP STAFF and their primary duties

Susan Calico, P/A II Microlab/IMPACT: Susan has designed and deployed

the new Marvell, Nanolab web site. She is currently working on a few

pre-release issues. Next up is the IMAPCT web site.

Madeleine Leullier, Computer Resource Specialist II

(Supervised by Katalin Voros): Madeleine oversees Unix and Windows accounts,

gives direction to members regarding computer issues, manages the HP Design Jet

plotter, and presents and maintains the computer group’s orientation to

new members. She also designs and posts documents on the Microlab web site

using a variety of technologies.

Todd Merport, P/A IV Microlab: I maintain our Unix servers, write and

modify applications, supervise, and do tasks necessary for the development and

maintenance of Microlab Computer Systems.

Olek Proskurowski, P/A III: Olek is primarily an applications

programmer. He worked on the MercuryWeb this last year and maintained the

Apache/Tomcat/BIRT installation. He also helps with system administration and

troubleshooting (especially, especially difficult problems).

Changrui Yin, P/A III Microlab/IMPACT: Changrui performs Windows system

administration tasks, database application development, and web site design and

maintenance.

VI.

Future Plans

This year we will be moving

into the Marvell Nanofabrication laboratory. In the new lab members will be using

Mercury lab management software for equipment control, reporting, accounting,

inventory, reservations, and problem tracking. Members should be pleased with

the software, but certainly there will be bug fixes, modifications, and

training needed with this new release. The computer group also will be working

with network staff to setup networking in the new lab and offices. The Hydra

equipment control system and the Resource and the Utility Monitoring System

(RUMS) will be installed and physically and virtually connected to the Mercury

system. Computer staff will assist with computer related aspects of equipment

moves and setup network communication as needed.

VII.

Summary

The Microlab computer group

maintained systems with a high degree of reliability. Several programs were

enhanced or created. The Mercury system has had all of its major modules completed

and tested with quite favorable feedback from key staff members. Infrastructure

and staff computers were purchased or upgraded and installed. Two new equipment

control systems, Hydra and ControlByWeb were specified, purchased, and hooked

into the Mercury system. Telecom infrastructure was specified for the Marvell

Nanofabrication Laboratory. A new web site for the Marvell lab has been

developed. Overall we have provided responsive, flexible, and reliable service.

VIII.

COmments

Changrui Yin

Windows

Systems Administration

o

Installed System Security and Recommended Patches.

o

Administered the Antivirus server and clients.

o

Installed and configured the Symantec 10.1.7 server to

handle the version 10 clients

o

Completed regular Machine shop web site maintenance.

o

Configured

o

Shrunk Rums database.

o

Tested, installed, and applied the Acronis Universal Restore software.

o

Built an Acronis server to backup and restore small hard

drives (<= 100 MB) which usually can't be recognized by the USB interface.

o

Backups completed for (cape, rums, mshop-server, microlab2,

microlab3, Microlab5 and micro antivrs).

o

Pump database development: I added pump service field in the

database table. It is updated

automatically every night according the predefined service schedule. New web

pages were created for easy database access.

o

Installed and configured the terminal server Microlab5.

Workstations

and Lab Equipment

o

Cloned uvscope, reichert, xdif, nanospec, ksbonder. and

created documentation.

o

Rebuilt staff computers. All of the Microlab staff have new

computers.

o

Upgraded memory on 3 Crestec computers.

o

I provided printer and computer software support.

UNIX

System Administration

Machine-shop

File Management System Project

o

Re-designed the Job Management System database to

incorporate a file management feature. Eight web forms were created to upload

files, update records and query data.

Moving

o

Coordinated office moving for BCAM/IMPACT students and

myself.

Future

projects

o

Build another rums server.

o

Upgrade the Micro-antivrs to version. 10.

o

Setup remote

scanning to determine computer patch status.

o

Assist with moving equipment and computers to the Marvell

lab.

OLEK PROSKUROWSKI

For the past year I worked almost exclusively on MercuryWeb part of the

Mercury system. All required functionality of the MercuryWeb has been

implemented. I also fixed several bugs in Wand system and assisted Todd in

system administration.

Mercury web

o

Added/updated tables, triggers, and stored procedures

required by new web modules.

research feasibility of using barcode printer/reader for use with

MercuryWeb.

Implemented/finished the following modules:

o

Accounting

Labhist

Research Groups

Reports

o

Purchasing

Purchase Orders

Vendors

Shipping methods

Billing/Shipping Addresses

o

Inventory (including using barcode reader for

chekin/checkout)

Add/Update/Checkin/Checkout

Inventory Types

Inventory Items

o

Resources

Equipment

Utilities

Facilities

Locations

Areas

o

Admin

Activity Rules/Types

Charge/Journal Rules

Groups

Fiscal Periods

Reports (including output to

PDF/Excel/Word/Powerpoint)

o

All current accounting reports.

o

Majority of tables can be viewed as a report.

System administration

Installed necessary security patches for

apache on mercury.

Wand

Fixed critical bug that manifested

itself after Solaris patch installation.

SUSAN CALICO

Marvell Lab Website

Working with the criteria of Bill Flounders and Katalin

Voros, this project creates a new Marvell Lab website that reflects both the

new lab and the traditions of the existing lab, and recruits potential members

while serving existing members. The site is compatible with IE6/7 and FireFox,

and includes menus and page design features of modern browsers. The site

utilizes many different modules and technologies:

- Logo and site design, based on

the old logo and UC colors, and serving the needs of current and potential

members.

- Fundraising meter using wafer

shapes and textures.

- Sponsor display, with rotating

sponsor logos (linked to sponsor’s website) and a photo or story

about the specific sponsor contribution the sponsor made to the lab.

- Tool move status display,

tracking tool up/down by class, detailed in a linked, spreadsheet-format

page.

- Vertical, fly-out menu, with

items from the existing Microlab menu.

- Private member pages requiring

login, with non-public information.

- Documentation

(ongoing) of structure and special processes.

Marvell Lab Website Plans for 2009

- Automation of tool status

display, from Excel spreadsheet to graphic display.

- Consistent look-and-feel for

all pages, using a single source (the current Microlab pages) for both

Microlab and Marvell lab sites.

- Modified logo/menu for the

shared pages.

- Page streamlining and

consolidation, to put relevant links at hand and reduce redundant website

maintenance.

- Cleanup of Microlab site

content as it migrates (or is cross-linked with) the new site.

- Graphic portrayal unifying the

two labs, to avoid confusion during the transition.

- Modification of site design, as

necessary and desired.