To: T.

King Liu, Associate Dean for Research

M.

Wu, Microlab Faculty Director

From: K. Voros, Operations Manager

Subject: 2008

Year-End Report

Date: 23

January 2009

I.

INTRODUCTION

While

Microlab operations continued in a steady state mode in 2008, many staff

activities revolved around planning for the move to the new lab. Our goal is to

keep operations running smoothly, on target financially, in anticipation for

the eventual transfer to the new facility. Grand opening of the CITRIS

Headquarters is scheduled for 27 February 2009; we do not have a date yet to

access for preparatory work the empty space of the Marvell Nanofabrication

Laboratory.

This is the 22nd

year-end report I am submitting.

II.

MANAGEMENT OF

RESOURCES

F a c i l i t i e s

Microlab

- Bob Hamilton,

Equipment and Facilities Manager, and Safety Officer of the Microlab,

provides details on upgrades, installations, facilities maintenance and

development in his report. Safety issues and HazCom improvements are also

discussed.

Notable in 2008: A

successful deployment and start up of the Crestec e-beam writer; new Picosun

atomic layer deposition system installation; major reliability improvement on

the Edwards sputterer and e-beam evaporator; software upgrade and reliability

improvements on the heatpulse rapid thermal processing systems; upgrade of the 6” resist coater control; pumps database

enhancements with maintenance schedule and notification capability.

- Process engineering

activities continued in high gear throughout the year. Sia Parsa, Process

Engineering Manager and his staff detail process support and development

activities.

Notable in 2008: Process characterization, manual writing,

user training on the two new tools,

crestec e-beam writer and picosun ald; updating all manual chapters with dates

older than 2006; completion of a major MEMS Exchange run, mask making and ETR

services.

Baseline

activities are an integral part of process engineering. The report on the

latest 0.35 μm run came out in December 2008. See http://www.eecs.berkeley.edu/Pubs/TechRpts/2008/EECS-2008-168.pdf

- Rosemary Spivey,

Administrative Manager and her staff’s reports include discussion of our

financial status, accounts and members administration, purchasing, and

inventory management. Recharge rate proposals were submitted on time for

both the Microlab and the Machine Shop and scrutinized throughout the year

by the Campus Recharge Rate Committee.

Notable in 2008: The

Microlab’s recharge budget passed the $3M mark, again in compliance for the 21st

year in a row. During the past five years we managed this with only a

cost-of-living increase in rates.

- Todd Merport, Computer

Operations Manager describes systems maintenance, operational improvements

and upgrades. Our computers and lab control software were maintained at

the highest levels of uptime and integrity.

Notable in 2008: Servers

and client systems are of recent vintage, all equipped with security programs;

major improvements in the pumps database.

In 2008 the Mercury project made excellent progress and it

is ready for deployment in the Marvell Nanolab. Equipment control hardware for

the new lab was purchased and tested with the Mercury interface. The MercuryWeb includes all interactive

programs, such as reports and forms, reservations and equipment qualifications,

along with management tools restricted to staff.

The Marvell Nanolab

website was established and activated in December 2008, http://nanolab.berkeley.edu/

New

Laboratory

Construction

of the new engineering building, CITRIS, including our new lab, the Marvell

Nanofabrication Laboratory is just about complete. Opening Celebration of the

CITRIS Headquarters is scheduled for 27 February 2009. At this time we have no

date for beneficial occupancy of the Marvell Nanolab.

We do not

anticipate shutting down the Microlab for the move; however, there will be slow

downs in selected areas. Planning is in progress. Details in Dr. Flounders’

report.

Machine Shop http://mshop-erso.berkeley.edu

The Machine Shop completed

387 jobs for 53 PIs in FY 2007/2008.

Financially the Shop has been struggling to maintain operations fully on

recharge basis. Staff reduction by one principal laboratory mechanician by the

end of 2007 helped move finances of the Shop towards a less precarious

situation; however, by March 2008 the account was still out of compliance. We

submitted a corrective action plan which was accepted by the Campus Recharge

Committee and the Shop closed the FY within the allotted out of tolerance

limit. During the first half of the current FY Shop finances are on schedule to

meet the budget.

S t a f f

Microlab

staff groups are organized along functional lines as described below. The Machine

Shop operates independently, under the Microlab Operations Manager.

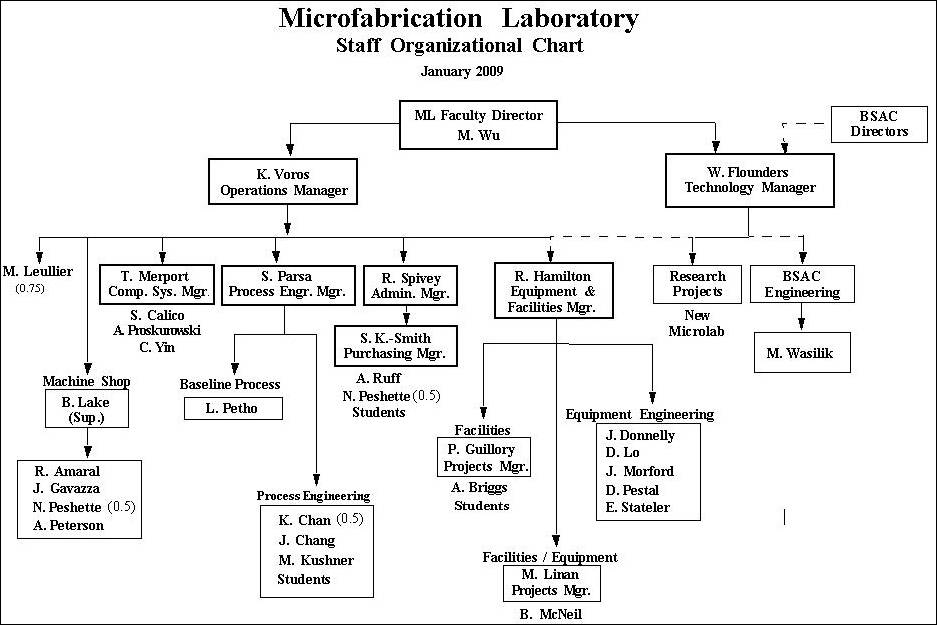

Table 1 - Staff Organizational Chart

The

Microlab has been successful in retaining and developing staff well tuned to

the laboratory’s needs. Cross training, back-ups and multiple responsibilities

in all positions ensure that lab operations have broad coverage and problems

are attended on a timely manner (Table 2)

|

Microlab Operations (25 FTE) Katalin

Voros, Principal Development Engineer, Operations Manager |

|

1.

Equipment and Facilities (10

FTE) Bob Hamilton, Principal

Development Engineer, Manager Joe Donnelly, Associate

Development Engineer David Lo, Associate Development

Engineer Jay Morford, Assistant

Development Engineer Danny Pestal, Assistant

Development Engineer Evan Stateler, Senior

Development Engineer Phill Guillory, Senior

Development Engineer, Supervisor Alan Briggs, Development

Technician IV Mike Linan, Associate

Development Engineer, Supervisor Brian McNeil, Development Technician V |

|

2.

Process/Baseline (7 FTE) Sia

Parsa, Principal Development Engineer, Manager Kim Chan, Assistant Development

Engineer Jimmy Chang, Senior Development

Engineer Marilyn Kushner, Junior

Development Engineer Laszlo Petho, Associate

Specialist – Baseline Attila Szabo, Associate

Specialist – MEMS 4 student assistants, 0.5 FTE each |

|

3.

Administration (4 FTE) Rosemary

Spivey, Administrative Analyst, Manager Nancy Peshette, Administrative

Assistant III (0.5) 2 student assistants, 0.5 FTE

each Susan Kellogg-Smith, Buyer II,

Procurement Manager Adrienne Ruff, Administrative

Assistant III |

|

4.

Computer Support (4 FTE) Todd Merport, Programmer Analyst

IV, Supervisor Susan Calico, Programmer Analyst

II Madeleine Leullier, Computer Resources

Specialist II (0.75) Olek

Prokurowski, Programmer Analyst III Changrui Yin, Programmer

Analyst III (0.5) |

|

5. Technology Management Bill Flounders, Principal

Development Engineer, Manager Xiaofan Meng, Senior Development

Engineer − Cryoelectronics Matt Wasilik, Associate Development Engineer − BSAC |

|

►

Machine Shop (4.5

FTE) Bob Amaral, Development

Technician V Robert Connolly, Development

Technician V Joe Gavazza, Principal

Laboratory Mechanician Alan Peterson, Development

Technician V (ML) Nancy Peshette, Administrative Assistant III (0.5) |

Table 2 - Operational Staff Groups

F

i n a n c i a l R e s o u r c e s

Recharge accounts under Microlab management continued to be closely monitored

for budgetary requirements throughout the year. Rosemary Spivey's report shows

details and financial analysis for each unit. (See Table 3 below.)

|

Unit |

Income |

Expenditures |

Performance |

No. of PIs Billed |

|

$3,016,506 |

$3,060,169 |

1.4 % [-] |

98 |

|

|

Machine Shop |

$361,626 |

$343,469 |

1.3 % [-] |

53 |

Table 3 - Recharge Accounts Summary

30 June 2008

Both units are financially stable and again closed

the fiscal year within recharge operation specifications.

III.

COMMUNICATIONS

& CONTROL

Change in Directorship

At

mid-year we were surprised by a sudden change in Microlab Faculty Directorship.

Prof. Tsu-Jae King Liu, our Faculty Director since June 2000, was assigned the

position of Assistant Dean for Research/ERSO Director, and Prof. Ming Wu took

over as Microlab Faculty Director. We are fortunate and pleased that again one

of our major PIs became the director, who cares for the well being of the lab

as much as we do. We are looking forward to a long and successful cooperation.

Membership

Microlab monthly membership was over 300 this past year,

same as in preceding years. Overall, we dealt with 491 members during FY

2007/2008. (See Table 4 below.)

|

Fiscal Year |

Membership/Month |

Lab Use-Hrs |

Sp. Equip. Use-Hrs. |

|

2000/2001 2001/2002 2002/2003 2003/2004 2004/2005 2005/2006 2006/2007 2007/2008 |

345 315 326 331 315 345 317 325 |

45,413 39,288 43,455 40,823 40,394 48,201 45,696 48,021 |

39,383 36,738 37,676 34,692 38,798 44,992 45,699 47,156 |

Table 4 - Microlab Utilization

Number of

Industrial members, BMLA, in January 2009: 22

Document Control & Training

The

Microlab’s operating manual consists of 1381 pages, compiled in 157 chapters,

available on-line from the web portal of the Microlab, http://microlab.berkeley.edu/.

Outreach

During the Summer of 2008 we again had two students

participating in our Summer Internship for High School Girls program. They worked

under the guidance of Jimmy Chang, Senior

Development Engineer, and Daniel Queen, a graduate student labmember,

who also worked part time for the Microlab during the Summer. We will continue

the program this coming Summer, http://microlab.berkeley.edu/text/MLOutreach.html,

for which we have selected two applicants from Bay Area high schools.

IV.

SUMMARY

The

year of 2008 moved along smoothly in the Microlab. Steady state operations continued,

with anticipation of the move to the new lab. Support from our PIs was

strong throughout the year, which meant

that we were able to end the fiscal year on target. Regrettably no funding is

in place for the move.